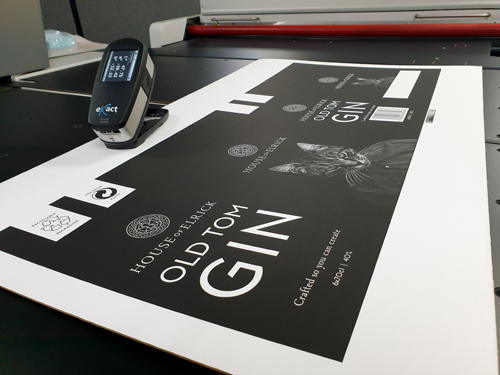

If a single image can show what a business is all about, the cat on the gin box is the one that does just that for Victory Graphics. The attention-grabbing combination of dark black tones, a fine image and bright reverse-outs are exceptional enough, but when you consider it was produced on a 20-year-old press using a single KODAK FLEXCEL NX plate, thus eliminating register issues and reducing cost, it becomes extraordinary.

Helping printers produce flexo packaging that combines such high quality and remarkable on-press efficiency is all in a day’s work for specialist flexo prepress business Victory Graphics, based in Portsmouth, UK. In the case of the cat image, the impressive print was produced by Newmarket-based Caps Cases, where print manager Wayne Booker, supported by Victory Graphics, is continuously driving print quality on such challenging jobs using Flexcel NX plates.

In 2016 Victory installed a Kodak Flexcel NX System, featuring a large-format 50″ x 80″ imaging unit capable of producing any size of plate. Looking back, Karl Pampus, Managing Director, credits the Flexcel NX System from Miraclon with setting the company on the path to the reputation it now enjoys in the corrugated market. “With Flexcel NX we can provide customers with a plate technology that’s superior – one that delivers not only consistently high quality, but also really significant production efficiencies and cost savings.”

Pampus goes on to describe the majority of Victory’s customers as independent corrugated plants that are striving for quality despite often having older, lower-specification presses. He says, “With Flexcel NX plates, the press can produce work that combines excellent coverage in solid areas with crisp reverse-outs and fine tones. In turn, this means we can reproduce both line and tone using just the one plate, instead of one plate for each. Essentially, we lift the quality these plants produce from standard to premium, giving them the ability to compete for work they previously thought was beyond their capabilities.”

The system’s combination of flat-top dot technology and advanced plate surface patterning makes this possible. Flat-top dots deliver true print consistency through true 1-to-1 reproduction between the digital file and the physical plate structure, while Kodak Digicap NX Patterning enables surface structuring to be applied to all print areas on the plate, including very small dots, aiding precise metering of ink for each print element. The plate surface can therefore be tailored to specific print requirements and press specifications.

Pampus continues, “Avoiding pinholes and areas where there’s too much ink not only produces brighter colours with reduced ink usage, it also allows the press to run faster. The even spread of ink on the plate gives homogeneous coverage, while the lower pressure results in consistently good transfer. In addition, lower-volume aniloxes can be used with associated savings on ink.”

There are significant operational benefits for the printers, adds Dean Darby, Operations Director. “Customers regularly tell us how much faster they get to colour, which reduces make-ready waste. And with Flexcel NX plates they don’t have to clean as frequently on long runs; we’ve had customers reduce cleaning by over 50%.”

In common with many Flexcel NX plate users, Victory sees considerable scope to transition litho-lamination jobs to flexo post-print and gravure jobs to flexo. One such opportunity currently under discussion with a leading brewery – the outer case for a premium-label beer – could yield five-figure cost savings with a switch to flexo. Pampus says, “What helps us in these discussions is Flexcel NX’s consistent ability to match proofs and samples produced by the incumbent technology – that consistency in delivering print results makes the difference. Sure, with other plate technologies it’s possible to get good results by tweaking parameters on the press, but with Flexcel NX it’s the certainty of getting results so quickly that makes press passes a routine task.”

Looking to the future for corrugated, Pampus expects the visual appearance of outer packaging to become even more important to brands, influenced in part by the acceleration in e-commerce in the wake of COVID-19 and the growing ‘unboxing’ phenomenon, whereby social media users share videos of product unpacking. “These developments will in turn put pressure on corrugated to achieve higher quality.”

He acknowledges that there are pressures on printers too – the perennial ones on prices and margin. “These trickle down to suppliers like us, of course, and our response is to become more efficient, more productive. We’ve invested just over £500,000 in the last year on measures to achieve this, including the recent installation of a new MIS.” Darby adds that last year the company also more than doubled the production area with the addition of a mezzanine floor – a sure sign of confidence in the future.

Victory is also responding by continuing to do what it has done so successfully to date: exploiting all the advanced features that set Flexcel NX plates apart from the competition, constantly seeking further improvement. Pampus concludes, “At the heart of the business are innovation and continuous improvement across our complete offering, all with the ultimate aim of giving printers the print quality improvement and cost reductions that will help them succeed as well.”