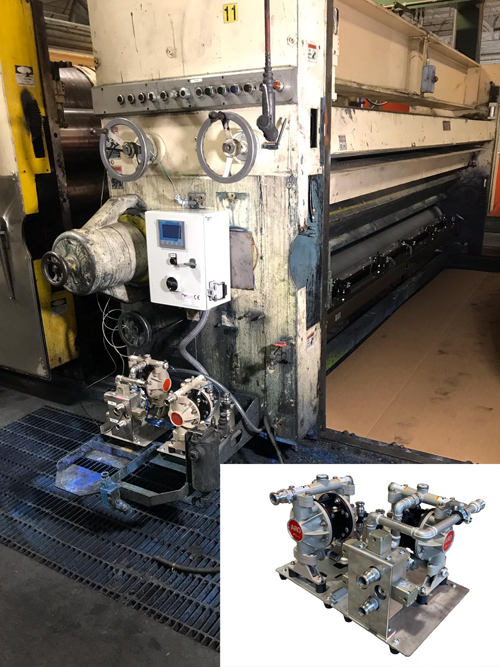

In February, two innovative BFT Flexo GT-Corr inking and wash-up systems have been installed on a Langston 196” jumbo flexo converting line in Virginia, USA. GT-Corr is a complete system, equipped with PLC, touch screen and a new manifold designed by BFT.

This BFT Flexo system is developed to give stable speed control of both the feed and return pumps during the printing process. The new BFT manifold is able to reverse the feed pump, allowing up to 100% recovery of all the ink present in the doctor blade system, as well as the supply lines. The GT-Corr system offers various wash-up options for complete cleaning of the blade system, ink lines and anilox roller.

Based on tests carried out during production changeover, 90% of the ink typically lost during wash-up, was recaptured by the BFT GT-Corr, as well as reducing wash-up water by 30% were observed. During a simulation with different units, for a four colour flexo printing machine with chamber doctor blades and 2800mm anilox length, an average of two changeovers per shift, two shift a day — a return on investment can be seen after only 10 months.

Additional options available for the GT-Corr system include ink temperature and viscosity control. The BFT GT-Corr system also offers on screen blade system pressure adjustment as well as blade life tracking.

Neil Livesey, President of Technoflex and American distributor of BFT Flexo says, “The GT Corr system was installed easily and our customer was happy with the results. The system has been operational for two weeks, with our customer seeing less ink usage and reduced changeover times. I would class this as a perfect compliment to any corrugated post-print machine.”