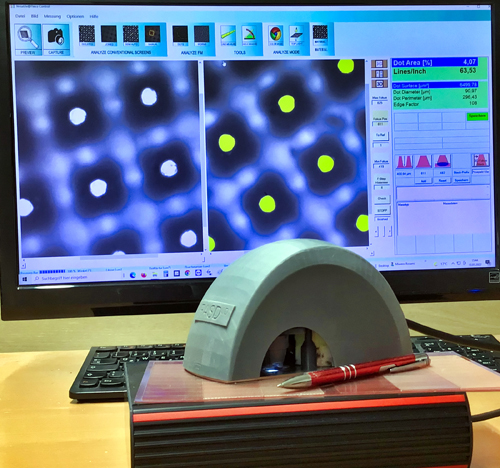

Sibress has just launched the new FADS3D mobile measuring device for two- and three-dimensional analysis of flexographic plates. Deployable anywhere and easy to use, Sibress FADS3D is a measurement solution combining full-featured capabilities in an exceptionally compact package.

The newly developed FADS3D is patent-pending and part of Sibress’ systematic drive to improve and evolve the FC3D series. It uses a high-resolution camera to capture the surface as well as the recessed sections of dots and their base on the flexo plate. In addition to standard plate measurement functions, the instrument enables precise depth measurements based on digital images captured using Z-stacking (focus stacking). In practice, this means that the FADS3D is also capable of accurately measuring the relief of flexo plates with a depth of more than 1350 µm. The increment per shot / layer is less than 5 µm when measuring in the Z-axis.

The new measuring instrument produces images that are razor sharp from the plate surface to the intermediate depths of the halftone dots and image areas. In other words, everything from the dot surfaces to the base areas of the plates can be visually checked in the Versatile@flex software using one and the same image.