FRIESE GmbH has not only used the challenging past two years to optimise processes and supply chains, they have also pushed ahead with and already tested some new developments.

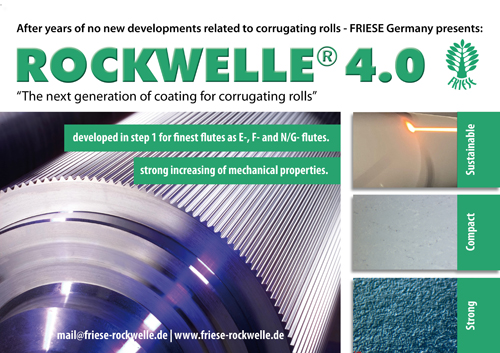

As the first of these developments, the new ROCKWELLE 4.0 coating can now be made available to a broad market. Rockwelle 4.0 is a completely new coating based on tungsten carbide that meets the highest requirements of today’s processes. The coating combines properties that are in demand today more than ever. It is sustainable, compact, strong and highly wear-resistant.

In a first step, the process was optimised for fine flutes such as E, F and G/N. This means, even the finest flutes which previously required an uncoated surface or chrome plating, can now be upgraded with the new Rockwelle 4.0 coating. In addition to the 10% higher material hardness compared to the previous tungsten carbide coatings, an enormous life extension can also be achieved.

“This first new development in corrugating rolls for decades required an enormous effort in terms of technical characteristics and input from our people and makes it clear once again that Friese is one of the key drivers for innovation in this field,” said Philipp Heublein, Senior Manager Sales and Service.