Reedbut Group has collaborated with BOBST on its latest folder-gluer upgrade. The implementation of a rear stack corrector on the VISIONFOLD 170 has allowed Reedbut to achieve a 20% increase in productivity within just three months of its installation.

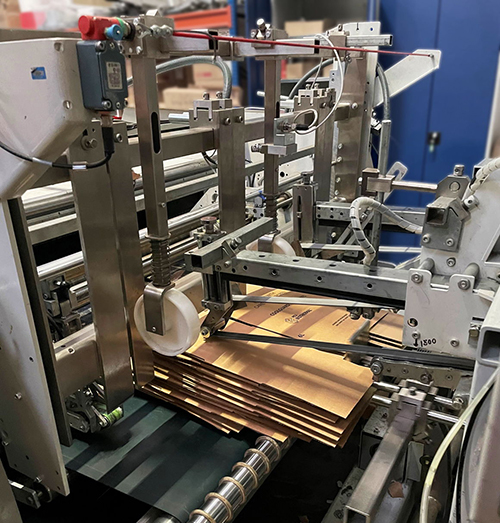

The Bobst rear stack corrector addresses the prominent industry-wide challenge of ‘fishtailing’, where blank stacks fall out of alignment when running at speed, resulting in folds that are misaligned and inaccurate at the closure of the lateral surface. The rear stack corrector squares up RSC blanks with low pressure belts and a mechanical pusher.

Stuart Deaton, Customer Experience Director, Reedbut, said, “We had the part fitted to our Visionfold 170 unit around three months ago, and we are already seeing a 20% increase in productivity. We were previously wasting a significant percentage of our material due to fishtailing, but now the rear stack corrector squares the blanks up perfectly and gives us precise gap control even in high-speed production. The upgrade has not only improved efficiency but also positively impacted our bottom line. The rear stack corrector gives us a crucial competitive edge in the e-commerce packaging sector, and we’ve only just scratched the surface.”

Mike Rice, Area Services Manager, UK, Ireland & Scandinavia, Bobst, added, “We are always saying that partnering with Bobst goes beyond technical discussions. Upgrades like the rear stack corrector show why that is. We’re in a market where carton converters are under pressure to deliver speed, quality and consistency, but not at the expense of sustainability, and in particular, waste. Waste is one of the most challenging aspects of modern high-speed production, but we’ve put Bobst innovation ahead with the rear stack corrector, which integrates effortlessly into the range of Bobst folder-gluers. The 20% boost to productivity that Reedbut has reported shows how everything is connected. With the right technology in place, more can be accomplished with less, all while controlling costs and reducing waste.”