The Germany-based die manufacturer, Marbach, developed a special technology for reverse cutting to save make-ready time some years ago. This technology, known as the height-adjustable anvil, is very popular in the market. Until now, the use of this technology has been limited to high-tech duramar tools or corrugated board tools. But the height- adjustable anvil is now also available in a new version.

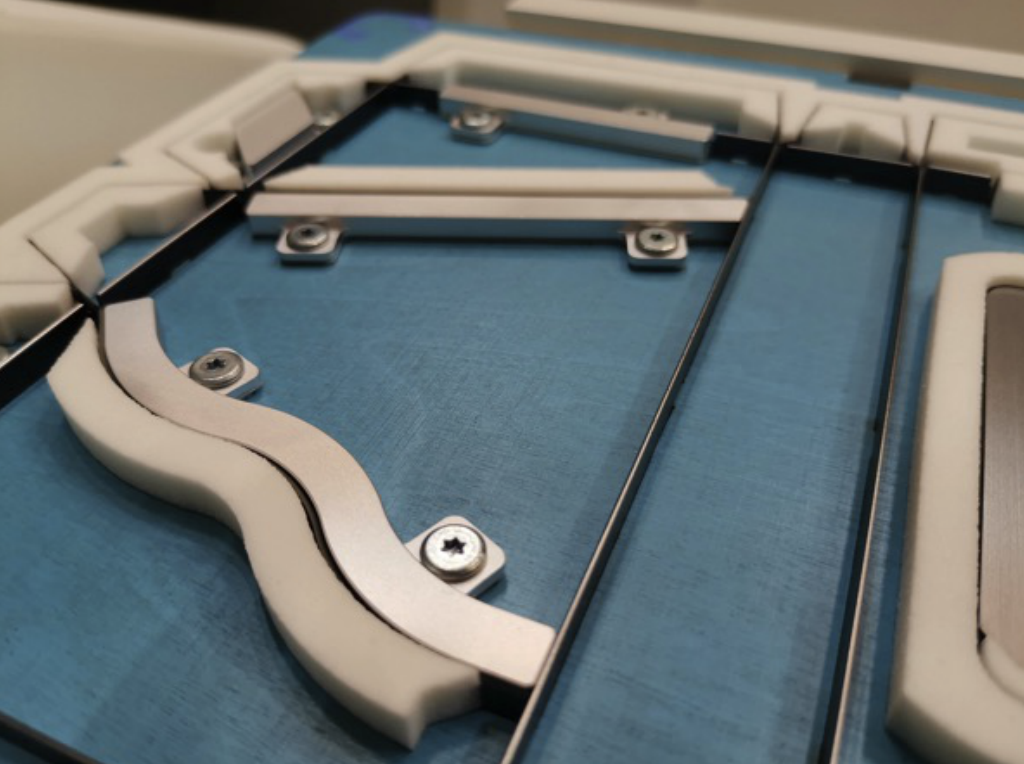

It was designed for folding box tools with wooden die boards (multiplex or greenplate). Due to the separation of the aluminum block into two parts, the wood of the die board is not compressed during the die-cutting process, but the cutting pressure is dispersed via the aluminum.

Research and Development Manager, Klaus Rommel, says, “By separating the aluminium block into two parts, the height-adjustable anvil can now also be used for tools with a wooden dieboard. Between the two aluminium blocks there are underlay foils. With these, each individual reverse cut can be quickly and easily set-up in height and optimally adjusted. For our customers, this means simple handling, reduced make-ready times as well as well- functioning opening mechanisms for sales-boosting packaging.” The new Marbach product is now available under the name “split height-adjustable anvil”.