Since 2004, Marbach has been using special technology to apply Braille dots to packaging at optimum heights and shapes.

The marbabraille technology has proven itself numerous times by Marbach customers in Europe. More and more countries outside Europe are now dealing with the issue of Braille on packaging and are increasingly using Marbach’s special technology.

In 2004, an EU regulation was issued in Germany, according to which a large part of pharmaceutical packaging required Braille. This presented many packaging manufacturers with new challenges. This was because applying Braille to packaging is a complex issue. There are conflicting requirements for such embossing: for an optically optimum result, the embossing of Braille dots should be weak so that the cardboard material does not tear. The higher the embossing, the greater the risk that the cardboard surface will tear open. For blind people however, a minimum height of the Braille dots is necessary so that they can easily feel the lettering with their fingers.

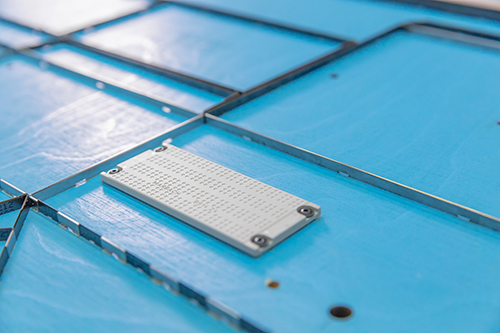

Consequently, applying embossing dots to packaging has always represented a balancing act between attractive visual embossing results and good readability for blind people. In order to meet official requirements and to optimally support its customers, Marbach at that time developed its special marbabraille-elasto technology with compressive elastic embossing. With this technology, Braille dots could be made in such a way that they could be easily felt by blind people, and yet the embossing did not leave any visible cracks on the packaging.

Bernhard Reisser, Industry Manager, Marbach, explains, “The demand for packaging with Braille embossing outside Europe has massively increased in recent years. Due to the emergence of the Braille issue in other countries, Braille embossing has become very topical again. We are pleased that with marbabraille we have in our portfolio a solution for optimally embossed Braille dots.”