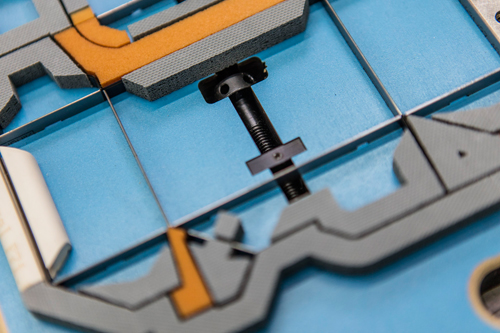

Marbach solutions ensure performance in packaging production. This is also the case with a tool technology that helps to adjust the tool in such a way that the print image and the tool can be quickly adjusted to each other if required.

The cosmetics industry in particular often uses costly printing processes and foil lamination. This high level of finishing can lead to warping of the sheet, resulting in the print and tool no longer fitting together perfectly.

Bernhard Reisser, Industry Manager, Marcbach, explains, “Since the misalignment between the cutting die and the printed sheet can usually only be detected in the die-cutting machine, the adjustment of the tool to the print image must be done quickly and easily. If this does not happen, there is a risk of production downtime and machine downtime costs. But this does not have to be the case. For some time, we have been offering our customers a special solution: a tool with register adjustment. With this technology, our customers can quickly and easily adjust their cutting-die so that the pressure and the tool fit together perfectly again. This not only leads to more flexibility in packaging production, but also to visually perfect packaging.”