Valmet has developed a new concept for quality oriented process control of corrugating machines. This includes cost- and space-efficient IQ Multipoint Moisture Measurement system and a new camera based IQ Warp Measurement for the combined board flatness control.

The IQ Multipoint Moisture Measurement sensor, a key component in the new system, has been developed to meet the need for a simple, small and cost-effective moisture measurement. The corrugating process features up to ten drying and re-wetting cycles, which, in addition to disturbances such as speed changes and raw material changes, increase variability and suboptimal process situations.

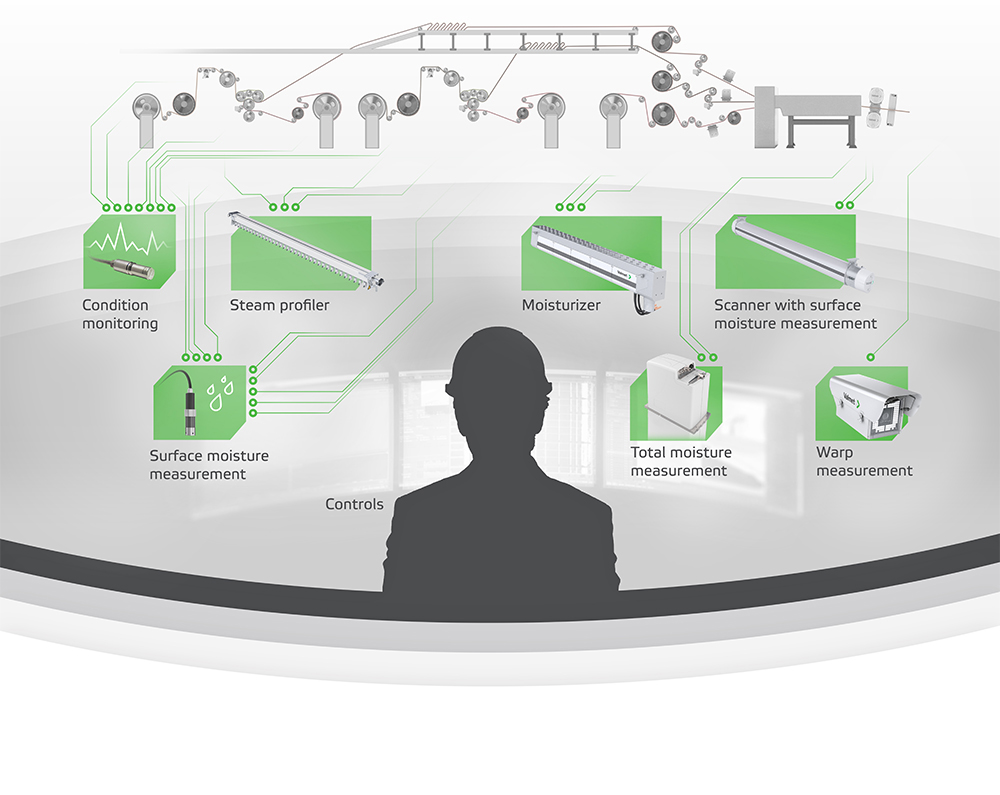

The system can utilize steam and moisture profilers and scanning sensors developed for, and utilized over many years in the paper and board industry. As well as the IQ Multipoint Moisture a new camera based warp measurement has been developed to meet user needs.

Valmet IQ is a customizable quality control, information and management solution that has been further developed to meet the needs of converting operations such as corrugated board and self-adhesive laminate production.