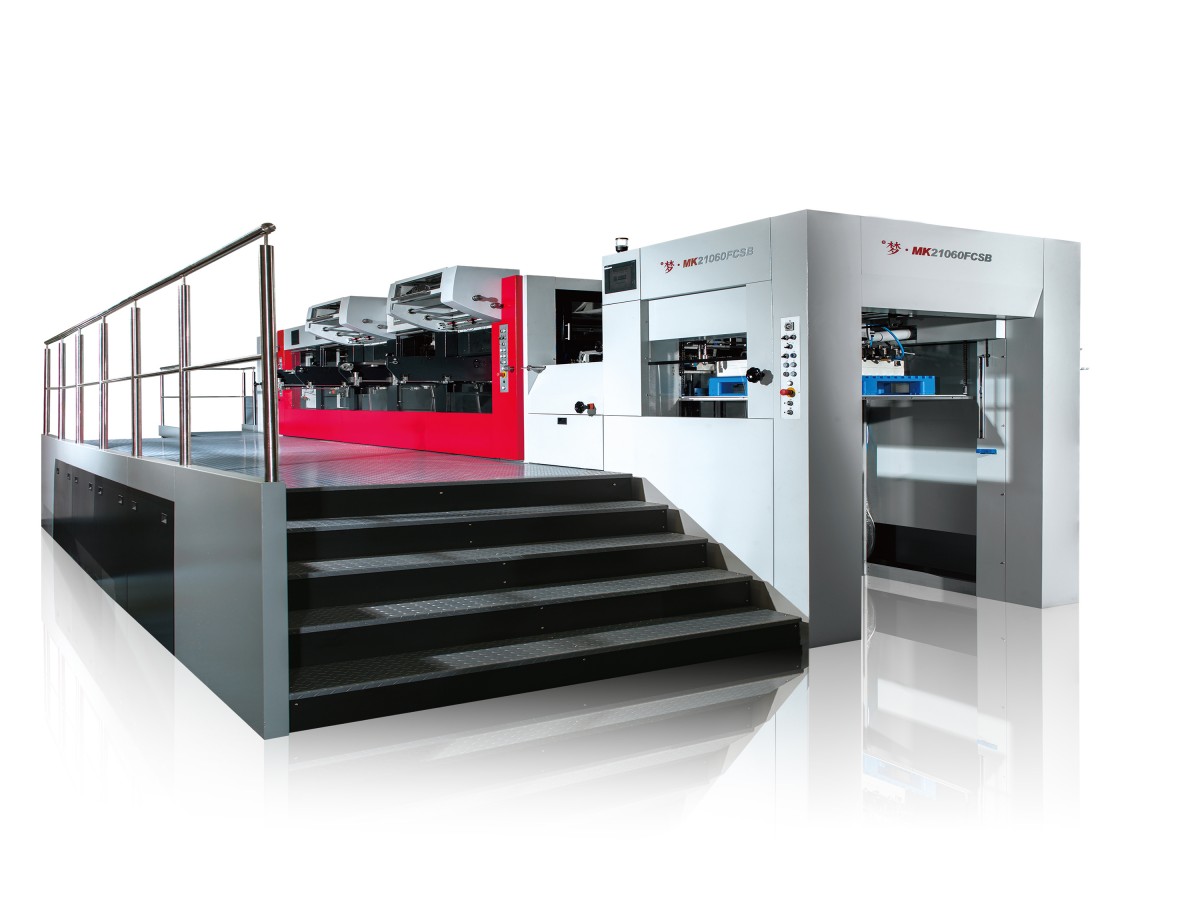

Masterwork USA, a manufacturer of folding carton and packaging equipment headquartered in Tianjin, China, is introducing its newest Duopress model: the MK21060STEs foil stamping and diecutting machine. It was designed to incorporate better stability, additional technology, and a faster maximum speed of 6,000 s/h.

“We’re pleased to unveil the Duopress MK21060STEs for the post-press market,” says Wayne Zheng, marketing manager for Masterwork USA. “Our expert research and development team have designed a new and exceptionally better computerized foil controlling system, which can handle complex foil advance calculations to help reduce foil usage of up to 60%. They’ve increased the speed on the Duopress to 6,000 s/h, which is really 12,000 s/h because it is producing three processes in one pass through the press: foil stamping, diecutting, and stripping. This new model offers maximum flexibility and can meet the exacting requirements to accurately register foiling, diecutting, and stripping processes in one pass which traditional machine processes are unlikely to deliver.”

The machine is designed with both foil stamping and diecutting functions in one pass. It can also be optioned to stamp two separate foil applications in one pass in its two platens. Operators will experience an increase in efficiency while reducing down time. The foil stamping system is equipped with three longitudinal foil advance pulls and two transversal foil advance pulls that are able to cope and offer flexibility on the most rigorous production processes.

An additional feature is a non-stop feeder. A pile change can be achieved while the machine is in operation with the help of non-stop swords. Adjustments on the feeder are made easy with micro adjustments.