More automation, simple operation and fast changeover – KAMA introduces a whole range of developments for print converting, embellishment and short-run folding carton production.

“We want to support job printers and packaging manufacturers to process the ‘critical’ short runs more easily and profitably and to benefit from the mega-trend towards versioning and small delivery units with our efficient solutions and streamlined processes,” says Bernd Sauter, General Manager, KAMA.

With 10 applications from die-cutting to embellishment, KAMA’s ProCut 76 Foil is considered a versatile finishing solution for B2 format. Now comes ‘Big Bite’, the new gripper that is able to transport substrates from 100 gsm to 3mm-thick cardboard. The ‘Big Bite’ gripper opens wide, both, upwards and downwards, so that voluminous substrates, heat-treated, wavy, laminated and corrugated sheets are guided safely through the machine. Even hardcover book cases of 3mm thickness can be finished with hot foil or debossing on the ProCut 76, opening up new fields of application.

The new AutoRegister AR³ for the company’s die-cutters achieves maximum register accuracy in finishing – even for sheets cut after printing or with multiple finishing operations. Servo motors align in x and y-direction plus skew adjustment. A useful and quality-securing feature for the demanding packaging market, such as refined folding cartons for chocolates, gifts or cosmetics. Also, this is interesting to reduce costs by printing in B1 format and finishing at high precision in B2.

Die-cutting, creasing and automated stripping & blanking without tools inline on the KAMA DC 76 die-cutter with the redesigned SBU stripping & blanking unit and now offering 30% more performance. Setting up the machine with the programmable SBU is even more operator-friendly and quick with the latest release of the JobManager software.

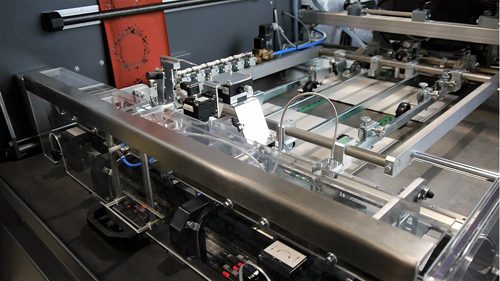

The final production step takes place on the FlexFold 52i folder gluer, providing full auto-setup and fast changeovers in just 5 mins. With the new inline AutoBraille (option), this efficient folder gluer becomes a solution for short-run in the secondary pharmaceutical packaging.

Both solutions – ProCut 76 and FlexFold 52i – can be connected to the printer’s MIS/ERP system for an integrated workflow.