Maintaining quality in the production process is essential and the latest product to assist in this regard is the ProofRunner Carton Retrofit. Jointly developed by Kohmann and EyeC (Quality Control Systems), as the name suggestions this print inspection technology can be retro-fitted to almost all currently available folder-gluers and provides the perfect inspection solution for folding cartons.

As required for most packaging materials for pharmaceutical, cosmetic, toiletry and branded products, the system inspects 100 per cent of the production and compares it against the signed-off proof (typically a pdf file). It uses the folder-gluer’s existing ejection device to reject any defective item and provides a full inspection report. As a result, quality requirements are met and unnecessary and time-consuming customer rejects are avoided.

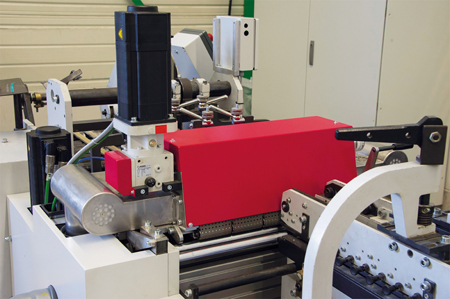

Available in two inspection widths – 400 mm and 660 mm – the ProofRunner Carton Retrofit is a self-contained unit which is integrated between the folder-gluer’s feeder and the pre-folding section – and adds only 800 mm to the overall length of the machine. It inspects the entire carton surface, including all flaps. Even if operated at a speed of up to 500m per min it is capable of detecting the smallest of defects, ensuring that the operator does not have to slow down production or compromise on quality standards.

The EyeC ProofRunner Carton Retrofit is quick to set up and easy to use, with an intuitive interface guiding the operator through the whole process. The inclusion of a high performance vacuum belt guarantees safe handling of all cartons, as well as their proper alignment. In addition, the unit is easily accessible for maintenance. It is available in the UK and Eire market through Friedheim International.