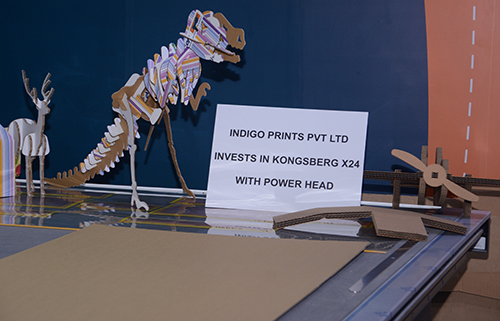

A successful IndiaCorr Expo was capped for Kongsberg PCS when the company sold the table on its exhibition booth to Indigo Prints Pvt. Ltd.

During the region’s leading corrugated event in Greater Noida, the manufacturer of promotional and display products acquired the versatile Kongsberg X24 Edge cutting table – with its high production speed, exceptional cutting quality and the ability to easily be upgraded as a business grows – for its New Delhi facility.

“As competition has increased in the FSU/POS/POD and packaging market, manufacturers have been focusing more on customisation and personalised solutions,” explained Rafiq Shaikh, Sales and Service Leader, Kongsberg PCS. “This trend has further driven the demand for short run and sample making, as it allows customers to visualise and approve customised designs before bulk production. The X24 Edge delivers a combination of tried and tested Kongsberg productivity, flexibility and best-in-class reliability, while the ability to cope with any material with fewer manual tool changes, extra fast tool loading, auto recognition and calibration completely transforms short runs and sample making. The sample-making process is particularly important as it can help manufacturers refine their designs and make necessary adjustments before full-scale production, reducing the likelihood of costly errors. The addition of the X24 Edge to its production line means that Indigo Prints Pvt. Ltd. can accomplish this with the strength, durability, and overall quality demanded by its own customers.”

To maximize the table’s productivity, Indigo Prints also acquired the Kongsberg PowerHead tool, which enables users to crease boards from microflute to triplewall and to V-notch 90-degree folds for bubble boards and board that can’t be creased.

Triedev J Kapoor, Director, Indigo Prints, said, “We are a growing business, and in order both to accommodate the new orders we anticipate and to expand our capacity, we were looking to add the latest machine with corrugated finishing capabilities to our facility. Not only does acquiring this new X24 Edge address our current sample making and short-run production needs, but it enables us to produce accurate, die-like finish samples for all types of materials. We are looking forward to putting it through its paces in the years to come.”