Heraeus Noblelight, a specialist for industrial light source solutions, is suppling UV LED curing systems for Peak Performance Speedmaster printing presses of Heidelberg. This DryStar LED curing system was developed in close cooperation and equips today now more than 1,000 printing units with more than 250 UV LED bars.

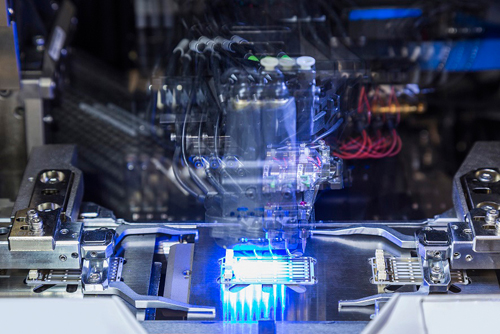

DryStar LED and other products of the Heraeus UV LED family ‘Semray’ feature special micro-optics on the LED arrays that gather and optimise UV radiation and minimise stray light. The UV LED curing unit delivers up to 30% more active UV energy to the product which results in high printing production speeds and the ability to print onto heat sensitive substrates. The negative impact of heat in the process can be eliminated. Printers using the new LED curing technology can take on new kinds of print jobs to expand their customer base and grow the business.

“The system runs at lowest energy consumption and still delivers highest performance during stand-by, wash-up cycles and makeready times. It automatically reduces power consumption close to zero,” said Martin Zibold, Product Manager DryStar -Technologies at Heidelberg Sheetfed.

The technology of Heidelberg’s DryStar LED system is designed for high demanding requirements of Heidelberg’s sheetfed offset printing applications: it delivers the highest dose at a high working distances due to its optical concept. DryStar LED achieves the best curing results even with high ink and coating coverage rates on paper and board no matter if coated, metalised or uncoated, even more on heat sensitive materials like plastics or foils. Combined with a higher up-time production range and no waiting times with Instant-start-and stop functionality the system can provide optimised price/sheet or sheet/hour performance, compared to traditional technologies.