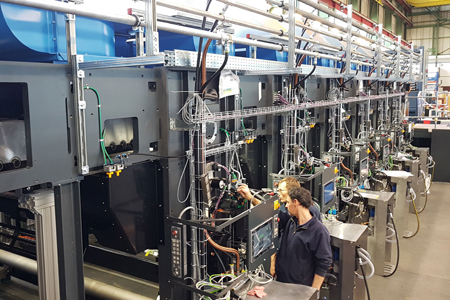

The Klingele Group and Koenig & Bauer are setting new standards in printing technology for packaging within the framework of a development partnership. Both companies have now reached a new milestone with the successful factory acceptance testing of the newly developed CorruCUT high board line rotary die-cutter by Klingele, after conducting a test phase with the prototype.

Koenig & Bauer completely redesigned the highly productive six-colour machine in close cooperation with Klingele and adapted it to the specific market and production demands. The CorruCUT will be installed and put into production in Klingele’s Delmenhorst plant as of August. The engineering design, the print quality achieved and the implementation of the operating concept not only impressed Klingele, but also received positive feedback from visitors from the corrugated industry worldwide.

Klingele will use the new machine to target market segments with high demands in terms of the print image and process reliability in packaging. These include in particular brand name companies, but also food manufacturers using packaging as an advertising medium at the point of sale.

The technical specifications of the new CorruCUT are geared precisely to these exacting demands; in addition to its excellent print quality, it offers high accuracy in printing and die-cutting, significantly reducing waste and increasing resource efficiency. With a working width of 2.8m and a feed rate of 12,000 sph, the CorruCUT is efficient; large packaging and displays are also easier to produce.

The machine has a rollerless in-feed so the sheets of corrugated board are fed gently into the machine to protect the material. The vacuum roll handling within the machine also ensures a significant reduction in wear and therefore less machine downtime and lower costs for spare parts. Automated data analyses will enable preventive machine maintenance in the future, thus avoiding unexpected failures.

“Koenig & Bauer has implemented the concept and technical innovations very well. The results that we have now seen in Würzburg have impressed us,” states Jan Klingele, managing partner of the Klingele Group.

Christoph Müller, member of the executive board at Koenig & Bauer, adds, “In the last two years, we have continuously built up a new team and consistently worked on the development of the machine. The focus on growth markets, such as conventional and digital packaging printing is part of the successful Koenig & Bauer strategy.”

The CorruCUT will be installed and put into production in Klingele’s Delmenhorst plant as of August.