Marbach has launched its latest development — digital zone levelling. It compensates and neutralises wear and production-caused disparities in the die-cutter. Jan Brunner, Head of business development at Marbach, explains, ‘‘Every die-cutting machine is subject to wear and tear in the daily production process. That’s why previously it was necessary to set-up all worn-out areas with make-ready tape for every single tool. This significantly increased costs, time and money. Digital zone levelling makes this process much more efficient. There needs to be only one zone levelling — this lasts for many months.’’

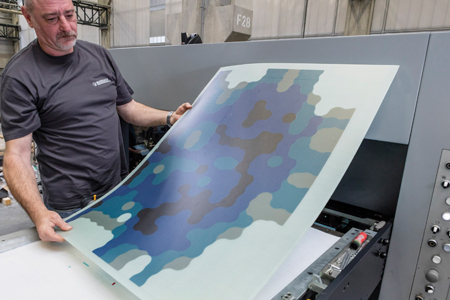

But how does digital zone levelling work? The operator makes an impression of the machine using a standardised process. With this, Marbach produces a new, modified vetronite plate for the make-ready sheet, individually for every machine. It compensates machine based height tolerances, so you need no area make-ready for every single tool.

Together with the Marbach innovations, such as magic sheet and mpower+, digital zone levelling almost completely eliminates make-ready time.