C&T Channel Matrix says it has noticed a trend to move towards lightweight and recycled corrugated and packaging liners, as the packaging industry strives to reduce the weight of packaging and save on raw materials. This can give advantages in terms of cost and sustainability, but there can also be technical issues with light-weighting leading to problems and downtime in production.

C&T has the expertise and a recently reviewed and newly packaged range of specific matrixes designed especially for corrugated conversion.

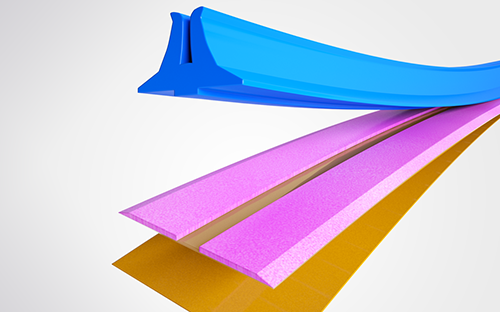

PINK Matrix is the result of years of R&D with engineers and marketing specialists based on requests from customers for a matrix which is both extra durable but also easy to skive. Manufactured from the patented ‘Rosadium’ material, this product is highly suitable for long-run or repeat run applications. It has an extra strong adhesive tape minimising delamination, a sharp chamfer and is easily workable.

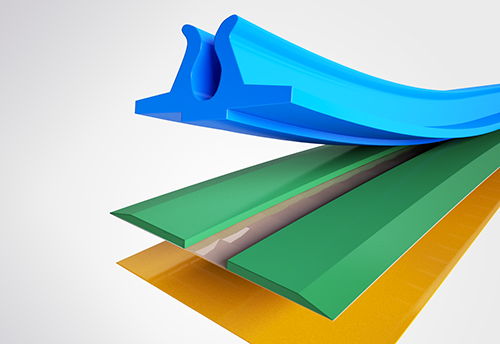

Corrugate Matrix is a creasing matrix designed specifically for corrugated board. It is ideal for thinner recycled liners and heavily printed litho-laminated products and is engineered to help eliminate cracking, registration, runnability and adhesion problems associated with creasing corrugated. The matrix also reduces knuckling by creating a holding form in which to crease. Corrugate base is much wider than traditional matrix, which gives a stronger adhesion to the plate, thus reducing movement of the matrix, poor registration, and even failure to crease. It is available in centred, U Bend and internal chamfer variations.

Stephen Williams, UK Sales Technical Director, C&T stated, “The pressure on production is at an all-time high. C&T can provide responsive support from small independents to large manufacturers – the challenges can be diverse and unique, but with our specialist products such as PINK and Corrugate we are confident we can help find solutions to the changing requirements of packaging conversion.”