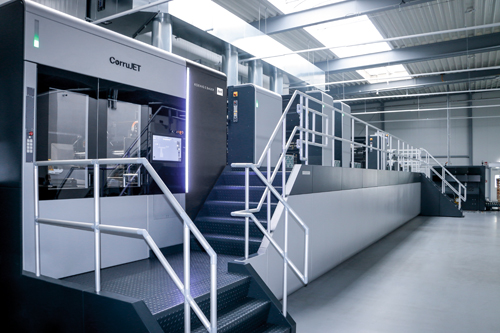

Koenig & Bauer Durst is proud to have achieved wider recognition for the CorruJET 170 press. Readers of Druck & Medien magazine in Germany chose the CorruJET machine as a winner in its prestigious ‘Drucker des Jahres’ (printer of the year) awards for the manufacturer category.

“Even though we couldn’t be at the planned ceremony because of the coronavirus pandemic, the readers sent a clear signal for digital printing by choosing the CorruJET,” says Robert Stabler.

He continues, “Awarded to Koenig & Bauer, this is a press that the corrugated industry has been waiting for so many years. It’s a segment that is ripe for digital transformation with run lengths declining and brands crying out for good, cost effective short-run and versioning solutions.”

Based upon extensive experience gained with Koenig & Bauer’s digital web press RotaJET, the CorruJET was developed specifically for the corrugated industry. The machine is a new overall concept for digital direct printing on corrugated board combining implementation of the latest technologies and functionalities with simple and intuitive handling.

Now part of the Koenig & Bauer Durst Joint Venture, it prints directly onto corrugated board. “The CorruJET is engineered for the highly efficient industrial production of corrugated sheets with top-quality digital printing,” continues Stabler.

Operating with a maximum production speed of 6,000 sheets per hour, the CorruJET can process corrugated board up to a thickness of 8 mm. It post-prints sheets of corrugated up to 1.7m wide at up to 137m per min, using water-based, food safe inks.

“As a result, the productivity is second to none in the post-print category and is ideal for converters with large volumes requiring mass customisation,” concludes Stabler.