One year ago, BOBST announced its vision to shape the future of the packaging world, offering a profound transformation of the packaging industry.

At its annual press conference, the company revealed several new solutions to support that vision, all built on the four cornerstones of Connectivity, Digitalization, Automation, and Sustainability, helping customers to deal with the packaging production transformation.

“We developed an ambitious vision and one year on, we are rolling out new solutions to help brand owners and converters to deliver better quality, efficiency, control, in a sustainable manner at a time when these qualities have never been more important,” said Jean-Pascal Bobst, CEO Bobst Group.

At the annual press conference, the company unveiled innovations for folding carton, corrugated and flexible packaging. For the corrugated board industry, these include:

– MASTERCUT 1.65. This is a completely new machine, especially designed for litho-laminated converting – and handles carton and corrugated board as well as litho-laminated, making it one machine for all jobs. Combining the advantages of folding carton and corrugated board flatbed die-cutters, it can process robust and delicate materials equally well, going from 300g solidboard to BC doublewall litho-lam. A sheet-to-sheet top feeder for delicate and sensitive substrates, a specially adapted POWER REGISTER and its high cutting force enable precise die-cutting, even for complex box designs and delicate substrates, ensuring an exceptional die-cutting quality.

The company says that this machine is also the only solution in the market for blanking in size VII and offers the possibility to deliver single cut, double cut and full sheets. Its good ergonomics with maximum level of automation and accessibility, as well as intuitive HMI ‘SPHERE’ also allow fast and easy handling for maximum productivity.

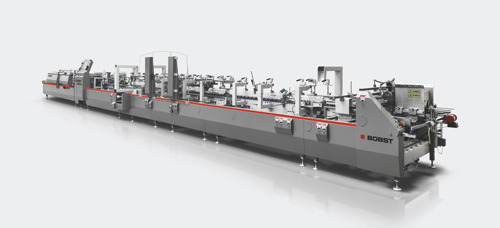

– SPEEDPACK. Available on the EXPERTFOLD 145/165, the EXPERTFOLD 170-350 and the MASTERFOLD 170-350m the Speedpack automatic packer will allow converters to realise the full potential of their Bobst folder-gluer. With the highest possible number of batches per hour and short set-up times, it increases productivity while preserving box quality.

Folded and glued boxes are automatically counted, stacked and banded, and perfectly formed bundles are delivered, ready for palletisation. Speedpack can handle all types of boxes, whether corrugated or litho-laminated, from straight-line, 4&6 corners, to crash-lock bottom. This means shapes and surfaces with various slip factors are not an issue for this versatile peripheral.

For the folding carton industry, these include:

– EXPERTFOLD 110 A3 Version. The new multi-purpose gluer features newly integrated modules for the dedicated production of crash-lock and 4-& 6-corners, which simplifies and shortens settings when changing box types. This reduces setup time during changeovers by as much as 80%.

– NOVAFOIL 106 Hot Foil Stamper. It provides efficient, versatile and cost-effective multi-colour foiling that enables quick setups and changeovers for highest productivity. This is the first in-line foil stamping machine from Bobst featuring a cross-foiling section. The platen section and gripper bar advance system have been redesigned and offer more pressure, longer dwell time, as well as smooth and steady sheet advance for amazing embellishment quality.

– ACCUREGISTER. Twenty years ago, Bobst introduced the POWER REGISTER. Today, Accuregister is a new version of this optical cut-to-print register. Available on the NOVACUT 106 range, it will reduce setting times and feed related stops, boosting productivity and delivering outstanding blank register quality.

– Digital Inspection Table – Folding Carton 106. This advanced digital solution suitable for format size 106 is a smart digital device that compares the production results with the customer’s original PDF. It actively monitors all points of the production process, from printing through embellishment and cutting including inspection of braille and embossing.