Having introduced the CorrBox Solution to the market in mid-2022 as a system for applying and monitoring adhesives in the production of corrugated packaging on flexo folder gluers, Baumer hhs has now set a new standard with an added function. Developed as an expansion of the CorrBox Solution, the new Bundle 24 function offers the option of automatically and reliably ejecting defective boxes with efficiency.

“Our objective with the CorrBox Solution was to rethink adhesive application and monitoring in corrugated production from the ground up.” explains Andreas Schneiders, Corrugated Business Development Manager, Baumer hhs. “The CorrBox Solution combines high performance with flexibility, giving our customers possibilities they never had before, which is why it has become a runaway success. The new Bundle 24 function is fully integrated in our Xtend3 controller, making the CorrBox Solution even more attractive to customers, because it takes them one step closer to zero-defect packaging production.”

Xtend3 controllers are known in the industry for being simple and intuitive to operate. Thanks to seamless integration of the bundle function in the control system, machine operators can now also access it on the Xtend3 controller’s 21.5-inch HD multi-touch display. In other words, they do not need an additional controller or a separate control cabinet for the Bundle 24 function. “After purchasing the Bundle 24 CorrBox set and installing it in their flexo folder gluers, all customers need to do is have our Customer Care team enable the bundle function. Right away, they can start taking full advantage of this convenient function to remove defective boxes from their process,” explains Schneiders.

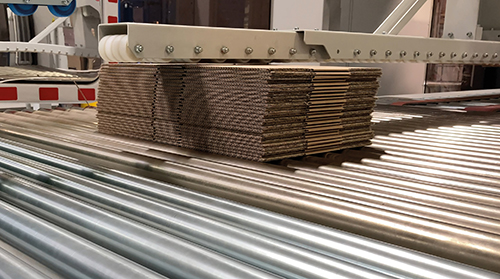

The CorrBox Solution reliably detects all defective products and, downstream of glue control, marks them on the side. The new bundle function tracks the defective boxes with the help of three light barriers right up to the end of the machine’s counting station, where it triggers a signal to the ejector to automatically remove bundles with defective boxes.

This efficiency gives Baumer hhs customers several advantages and sets the Bundle 24 function apart. Time permitting, bundles with defective products can be removed by machine operators. There is no need to interrupt production and the machine can continue running at full speed. “Our customers also don’t have to colour-code the bottom box in a bundle, which just generates additional waste. Our Bundle 24 function eliminates this practice, enhancing sustainability in packaging production. What is more, our solution does not need expensive camera systems for the ejector signal. In short, quality control in flexo folder gluer processes, with the aim of zero-defect production, has never been so easy and efficient,” says Schneiders.

Baumer hhs customers can use any common ejector on the market with the new Bundle 24 function. “A wide range of flexible solutions that can be adapted to specific needs are available on the market for automatically ejecting flawed items. Examples include ejectors with integrated strappers for making bundles, or ejectors with ball transfer tables for low wear-and-tear during continued processing. We don’t force our customers to work with a specific type of ejector that doesn’t meet all their production requirements,” concludes Schneiders. “In developing the CorrBox Solution system, we redefined adhesive application and monitoring in the production of corrugated packaging, and we took the same approach with our new bundle function. Consequently, it gives our customers in the corrugated industry new options for optimising their processes.”

The new Bundle 24 function from Baumer hhs is available immediately for both new and existing CorrBox systems installed on flexo folder gluers.