Ammeraal Beltech Circle Link belts are modular products molded from recycled plastic belts. Circle Links offers an expanding selection of belts and materials, including well-established products such as uni JCB, uni QNB, and M-QNB belts.

When worn down, plastic belts are thrown away as they have no further use. But what if that was not the end of their journey?

Ammeraal Beltech has developed a product that proves that broken plastic belts can be recycled and transformed into new ones — just as efficient, and even more sustainable.

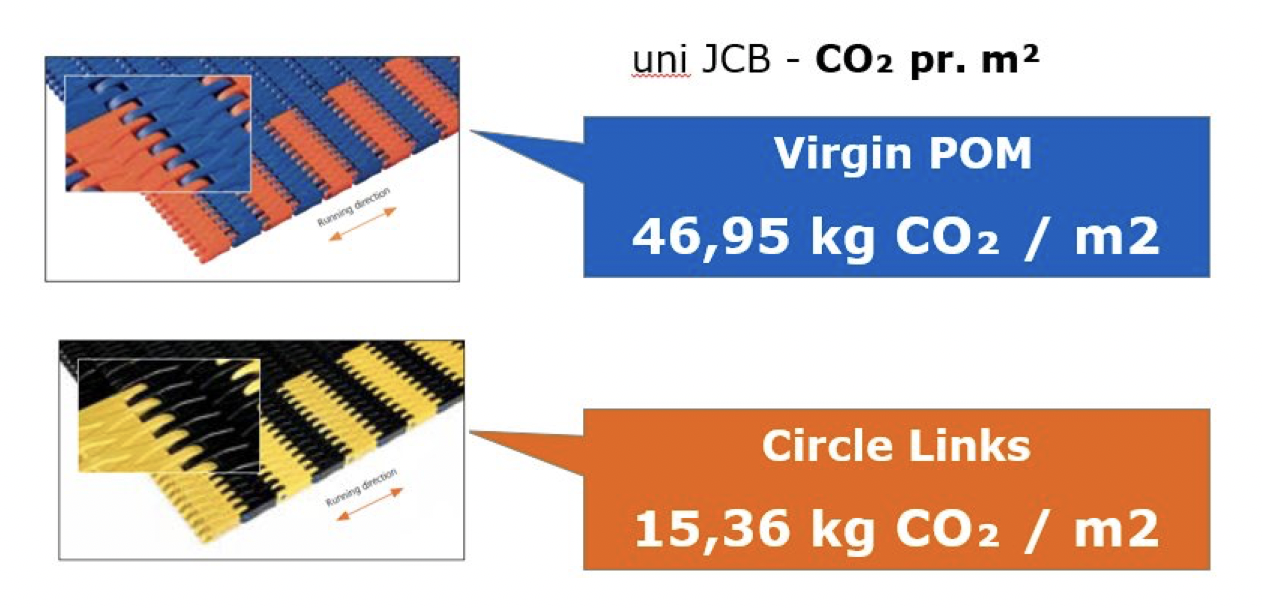

Circle Links belts are made of recycled polymers. They provide performance just as reliable as modular belts made of virgin plastic. At the same time, they help conserve resources and reduce waste and CO₂ emissions.

To make Circle Links belts, Ammeraal Beltech first collects their damaged and worn-down plastic belts. Next, patented technology for plastic resin sorting is used to recycle the belt. Finally, the recycled polymer material is reused in a new link with up to 100% recycled material.

Circle Links are the first and only recycled modular belting solution with a take-back program on the market. Take-back program means that customers can return uni belts at the end of life (material restrictions apply) and save on incineration costs. This material is used to make new Circle Links belts.

Circle Links come in three different colours: soft hazy yellow for the corrugated industry, with colour additive for safe walk edge markers, colour of the day, free from colour additives, or black – if your application requires color consistency.

Circularity is becoming the new quality standard and performance indicator. Companies are expected to back up their sustainability claims with real CO₂ reductions. When purchasing Circle Links, it will come with certificate of your reduced CO₂ carbon emissions.