C&T Channel Matrix is continuously working with customers to ensure they achieve the best creasing results to optimise product and machine performance.

Celloglas is a UK-based print finisher with three manufacturing sites. With a wealth of experience from a wide range of markets, it prides itself on adding value to printed matter, often working directly with printers, print management or designers.

“Celloglas requires a special range of creasing matrix that can cope with a diverse range of substrates presented by the challenging callipers of paper and board – 200 micron through to 1200mm – all requiring the optimum crease,” said Howard Mead, Group Commercial Director at C&T Matrix.

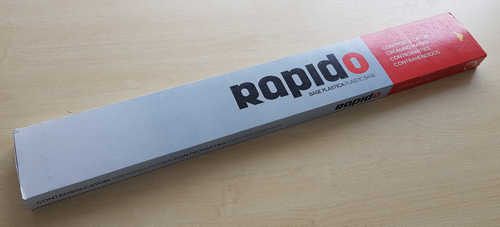

By working with the team at Celloglas, C&T has been able to trial and recommend its range of Rapido matrix – a new PVC creasing matrix which features a special shoulder radius to optimise sheet transfer, and a routed channel for additional strength.

“Rapido is ideal for Celloglas as it is a flexible matrix with a range of speciality creasing profiles including off centre, mini and multi crease. It can overcome the many challenges Celloglas faces with its diverse range of creasing needs,” added Mead.

Rapido is manufactured from high quality PVC as a single piece creasing matrix for extra strength and accuracy of the channel width and shoulder height. The external shoulder has a rounded chamfer for smooth sheet transfer and eliminates unnecessary stoppages. It has strong adhesion to the plate – the matrix does not move during use but can be cleaned, leaving no residue.