We set up a Zoom conference (other services available as well!). We chatted for an hour – me, Brian Seggar, Director of Everest Packaging Group, Tim Straker, Sales Director at Fosber, with his colleagues Simone Roberti, Director of Operations, Icilio Disperati, Senior Project Manager and Nicolò Giusti, Marketing Specialist. Since the outbreak of the COVID-19 pandemic, it seems that virtual meetings are now the new norm. The ability to communicate, collaborate and get things done without having to be face to face might be one positive thing we all take away from this awful situation.

This is exactly what happened in Johannesburg, South Africa recently, when Everest Packaging Group was entering the final weeks of installation of a new 2.5m C/Line corrugator at its new sheet feeder site, Everest Corrugated. With containers arriving from Italy in readiness for a 45 day installation, the timing of the project could not have been more troublesome, thanks to the incremental lock-down around the world that rolled out during the first quarter of the year.

Who Are They?

Everest Packaging Group is a collaboration between two leading sheet plants – Pride Pak Packaging (Pty) Ltd and Boxlee (Pty) Ltd. The two companies had grown significantly over the last few years and it was now looking like it was time to invest in a corrugator. Between them, they established a new facility that would act as their own group sheet feeding operation. Everest Corrugated was set up in 2019 with the primary objective of supplying the highest quality board to the two sheet plant businesses.

“I have known the owners of Pride Pak and Boxlee for some time,” explains Seggar. “Both Yagnesh Gosai and Justin McLeod have ambitions to grow their businesses, but to really accelerate and get into some of the big multi-national companies and also the agriculture market, you have to be integrated and be in control of your board supply. This was stopping them from getting to the meeting tables, so they took the bold decision to put their businesses into a new Group structure and so was born Everest Packaging Group.”

Big Opportunity

The agriculture market accounts for between 30 and 35% of the South African corrugated demand. That, coupled with multi-nationals such as AB InBev and Unilever and you can see why the owners of the two sheet plants wanted to take steps to allow them to get into these markets.

“After significant strategic debate amongst the partners, I was asked to set up a dedicated sheet feeder and we started the planning in late 2018,” explains Seggar. “I had a background in board production and larger company structures, so setting up this facility was a nice new challenge for me. Today, we have 45 people working on a double shift basis, operating from a facility in Johannesburg South that covers 8,500 sqm.”

Being part of the Everest Packaging Group, it was important that transparent communication between the Group businesses was implemented. As both Pride Pak and Boxlee run Abaca’s cost-estimating and business system, it was a logical decision to install Abaca at Everest Corrugated as well. Coupled with EFI for planning, the plant offers total visibility for the partner companies at all times.

Fosber Chosen

“We knew Brian very well, as he had been running Fosber units within the various companies he had been associated with over the last 10 years or so,” explains Straker. “For example, he was General Manager at a sheet feeder for another group who were running Fosber equipment, so when Brian and his colleagues approached us in late 2018 to look at the feasibility of the project, we knew we would be a good partner for them. But we didn’t come close to imagining how hard we would have to test the relationship!”

The C/Line corrugator is a 2.5m machine, configured to run single and doublewall board. It is capable of running at 250m per min, producing B, C and D flutes and combinations thereof. Considering the large amount of agricultural (especially citrus fruit) packaging that Everest produces, the standard C/Line has been fitted with a heat-booster pack on the Concept gluing zone. The triple heater has a curved steam infusion hotplate booster on the upper level and an increased 1100mm diameter drum on the middle level. The glue unit has a curved bottom liner booster heater at entry to the machine, while the double backer has an extended heating section with 16x 750mm hotplate arrangement, with three independently controlled steam pressure zones.

To maximise production capacity when running single wall, the bridge and Syncro4 corrugator control have been personalised to allow the second Edge single facer to simultaneously produce single face that is fed directly into a Pivab slitter rewinder.

The line is also equipped with Fosber’s Pro/Care intelligent on-line maintenance manager, which plans and schedules the required maintenance to be carried out according to actual production produced on the corrugator. It comes complete with step-by-step animated 3D video instructions illustrating how to carry out the planned maintenance procedure.

Pro/Care’s CMD (Corrugated Machine Diagnostics) module provides constant on-line diagnostics by monitoring all the main motors and air consumption on the corrugator in real time, instantly cross checking this data with the actual production and process conditions. In this way, the system can intelligently detect anomalies and potential malfunctions on the corrugator, automatically notifying Fosber’s customer care department and Everest’s engineering staff whenever readings exceed the expected tolerance bands.

On Schedule

“We were reaching a stage where about 95% of the mechanical works had been completed, but only about 80% of the electrics,” explains Seggar. “That is when we got a call from the Fosber team to say they were having to recall their entire engineering team, due to the lock-down in Italy. I must admit, we were pretty concerned, as we were so close to finishing the installation with them and ultimately, I was running a very tight project that needed to get operating as quickly as possible. What transpired was truly a collaboration of like-minded individuals who would not accept defeat as an option.”

“We certainly had a couple of sleepless nights,” recounts Disperati. “I spent hours and hours on the phone with Simone Roberti as we tried to figure out how we could possibly get this machine up and running. We put in place a really dedicated team of engineers and rolled out a detailed plan of action, which was agreed by Brian and his team and our team back in Itlay.”

Roberti adds, “We created a series of tasks that could be shared and managed by all the key people. Using Pro/Visionair, WhatsApp, video conferencing and regular calls, Brian, Icilio and I could follow the progress of the project as it unfolded. We were also lucky that the technical team Brian has at Everest Corrugated are all strong in their own fields and this meant we could carry on with the installation, even after our engineers had been recalled.”

“When we looked at the fire-power we had in terms of engineers who were stuck in lock-down at home, we realised we had the opportunity to dedicate individuals to specific tasks,” continues Roberti. “One thing came to light though – each engineer had to be precise and very clear with their instructions, as this had to be transferred to the plant team at Everest. We assembled the best team possible, who all dedicated 10 hours each day to the start-up phase.”

“For completion of the remote installation and machine testing, we had the services of Matteo Bonuccelli (Mechanical Foreman), Francesco Rocchi (Software Engineer), Samuel Bicicchi (Electrical Foreman and Electronic Engineer) and Roberto Quilici (Machine Testing Supervisor),” explains Disperati. “During the start-up phase and for production supervision, Matteo, Francesco and Samuel were then joined by Giovanni Bonassin (Product Quality Specialist) and Alessio Lunardini (Machine Testing Engineer).”

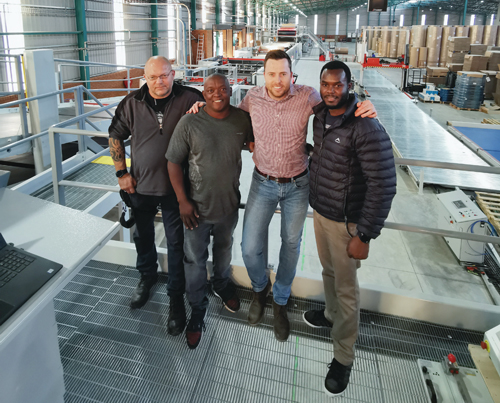

Thanks to the Pro/Visionair helmet cams with integrated microphones, Everest team members were able to continue doing the last bits of work, with the guidance of the Fosber engineers. “Our Engineering Manager, Eugene Beytel and his colleague Russel Meyer have good experience with Fosber equipment, although not the latest technology,” says Seggar. “But we have a good in-house team and over a quarter of them had run a Fosber line before, so once we followed all the project phases, we were able to handle start-up of the line with the Fosber technicians looking on remotely.”

Thanks to the Pro/Visionair helmet cams with integrated microphones, Everest team members were able to continue doing the last bits of work, with the guidance of the Fosber engineers. “Our Engineering Manager, Eugene Beytel and his colleague Russel Meyer have good experience with Fosber equipment, although not the latest technology,” says Seggar. “But we have a good in-house team and over a quarter of them had run a Fosber line before, so once we followed all the project phases, we were able to handle start-up of the line with the Fosber technicians looking on remotely.”

Seggar concludes, “We achieved start-up successfully, only one day behind the planned project time line. When I look back at the work we all undertook, it is nothing short of a miracle we were only one day late. The team work, project planning and the desire to get it right has resulted in a remarkable achievement for which we are hugely thankful to all those involved. It just shows, collaboration and a desire to succeed really can get you over any mountain in your way.”