Web-to-pack is more than ‘just’ putting an online shop for folding cartons online. It is a basic philosophy for making your business and the entire workflow organization fit for the future in the age of print 4.0. The first providers are already operating successfully in the market. With consequences for print shops with a conventional business model.

‘Impossible!’ – it is not unusual for success stories to start like this. So too in the printing industry. For example, when the first online print shops started popping up almost 20 years ago. Standardizing printed matter so that it can be costed and automatically produced at the touch of a button? An estimated 99 percent of commercial print shops thought this was a fantasy. Today, web-to-print is flourishing. Sales and market shares are constantly growing. Nevertheless, “impossible!” is now being muted by the packaging printers when it comes to web-to-pack.

Admittedly, folding carton printing is much more complex than advertising printing, if only because of the finishing and topics like serialisation, colour migration, or colour consistency. On the other hand, however, technology has made a huge leap forward in recent years. “Highly automated machines, intelligent software and a connected, digital value chain have smoothed the path towards online printing – including folding cartons,” explains Bernhard Schaaf, Senior Manager Digital Printing at Heidelberg.

Fundamental paradigm shift

However, web-to-pack involves much more than attracting orders via a web shop. It is a paradigm shift away from the individual production of an order and towards custom large-scale production using standardisation and automation. “Through this companies gain agility, speed and efficiency. That is exactly what is required to keep up with the most urgent market trends and customer needs,” says Schaaf.

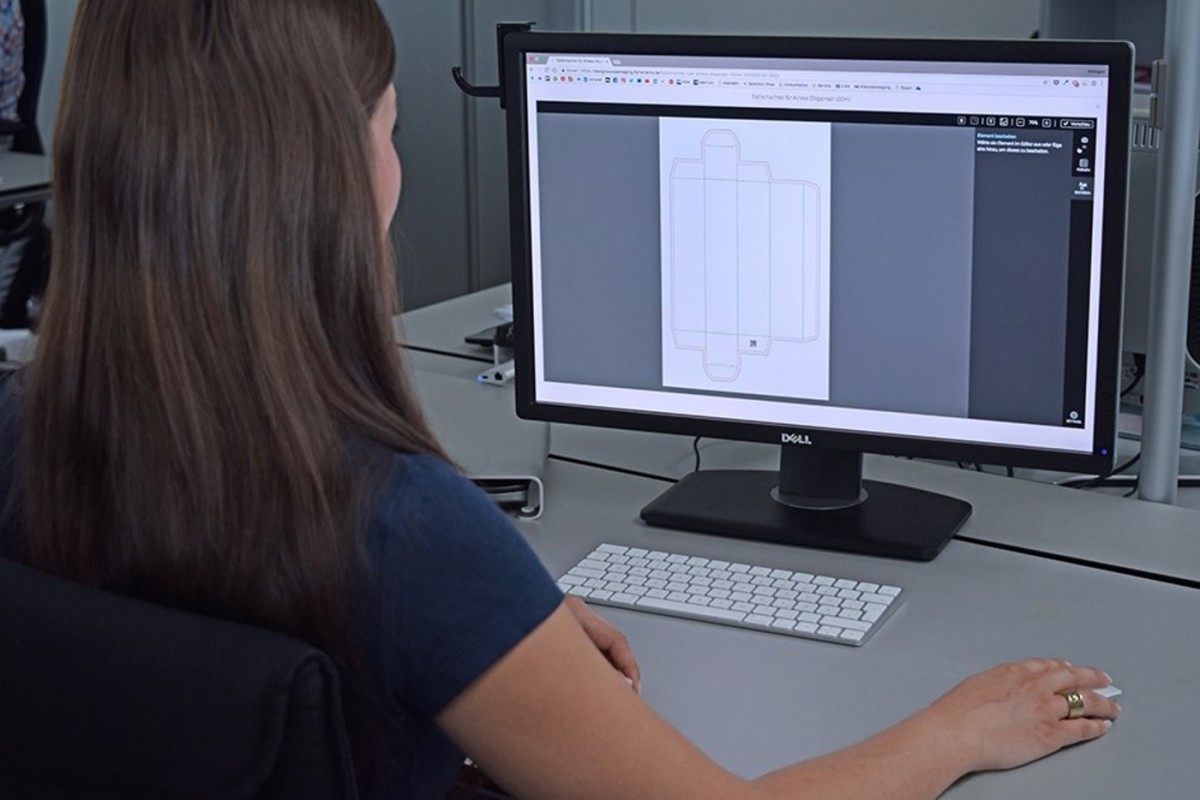

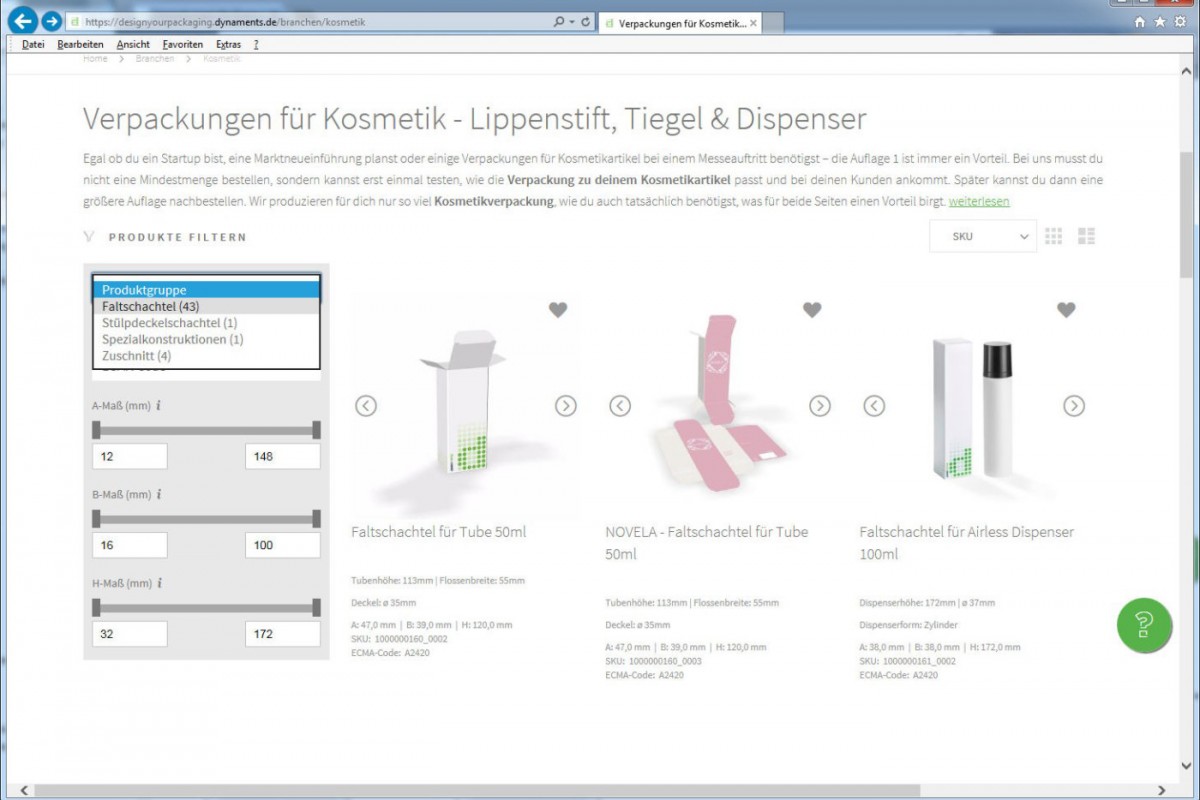

Example of a web-to-pack online shop (Source: designyourpackaging.de by colordruck Baiersbronn).

Speed is now the most important added value for customers, both in the B2C and B2B segments, especially in the face of personalisation, customisation, faster innovation cycles and a shorter time-to-market. Web-to-print print shops now even offer a next-day delivery, a service that customers are will to pay a premium for. In addition, customers want to be able to order their products, compare prices and check the delivery status in real time around the clock.

Gaining new customers and protecting the core business

The interest in web-to-pack is therefore great. “The print shops already offering this on the market are doing good business. Smaller companies in particular want to generate more business with new customer groups with an open shop,” says Schaaf. The demand is there. One company that offers folding cartons online for the food industry achieved five-digit sales figures in euros within a very short time. The principle here is that the print shop offers a limited choice of carton formats and parameters, for example for spot colors and embellishment. The customer configures their product online and receives personalized folding cartons by taking advantage of options such as uploading their own pictures. In return, the print shop gets a standardized order which it can produce quickly and cost effectively in gang runs and without changeovers.

Other print shops, on the other hand, set up a closed shop so that they increase the loyalty of existing customers through additional services, and in this way protect their core business. Being able to reorder folding cartons online at any time, possibly with the option of the customer being able to make minor changes to the layout within the predefined framework, is an example of a typical value-added service.

Blueprint for optimized internal workflows

Embracing web-to-pack is worth it even for packaging printers that produce large annual quotas. Even if just to reduce the high stock levels. Because web-to-pack provides the blueprint for internal process optimization. “Through highly automated processing from order receipt to invoicing, you can speed up the workflow organization,” says Schaaf. Standards ensure lean production, while the software-controlled workflow ensures short throughput times. The software organizes the whole process: it checks the job data, assigns the jobs to gang runs, and sends them to the corresponding production line. “Fewer manual interventions mean fewer errors and costs, and therefore greater speed and flexibility,” explains Schaaf.

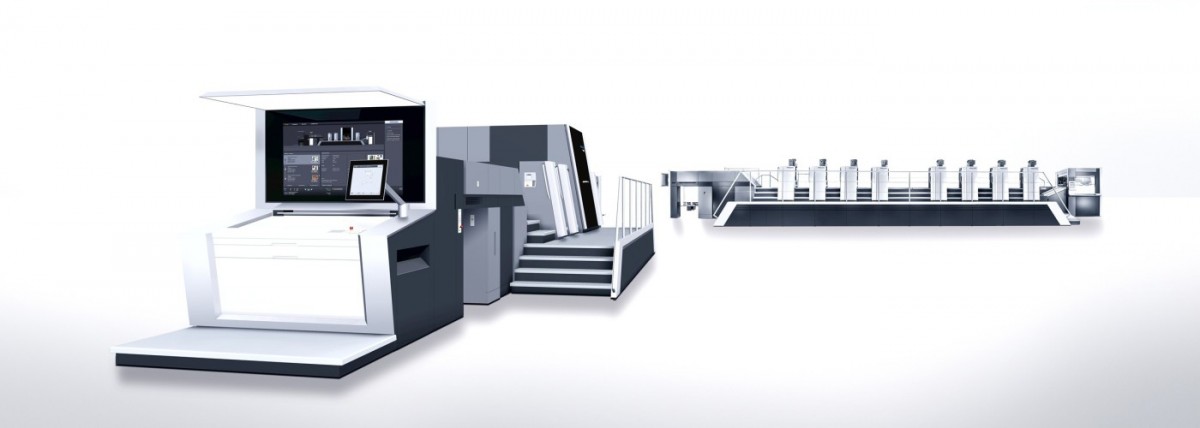

Primefire 106 and Speedmaster XL 106

Faster time-to-market with lower costs

The example of a customer from the pharmaceutical industry is evidence that it works. The background: increasing numbers of ever smaller jobs with ever shorter delivery deadlines are pushing conventional companies to their limits. Throughput times and effort are going up. The margins are going down. “The company therefore made the change to web-to-pack. It can now produce at much faster speeds and much lower costs,” reports Schaaf. “This is because the standards tailored to the production environment make it possible to bundle and efficiently process the multitude of orders.”

In addition, web-to-pack allows the company to increase customer loyalty through services that an analog print shop cannot offer, such as supplier-controlled inventory management. The customer’s ERP system automatically triggers an order in the print shop’s web shop as soon as a defined minimum inventory of folding cartons is reached. The added value: both sides save time and storage costs and the print shop secures sales at the touch of a button. “As pure suppliers, print shops are under threat in the price competition in the market. But a print shop that controls the data interfaces with the customer through an online portal has a clear advantage,” says Schaaf.

Exploiting the advantage

One thing is sure: a company that does not want to place its own market position at risk must give its customers what they want. Web-to-pack helps with this. The tools are available. Even fully digital production from printing to coating application to die cutting is possible – and therefore also cost-effective production down to batch sizes of one.

“Early adoption pays off,” concludes Schaaf. “You just have to look back to the beginnings of web-to-print. The forerunners set in motion a spiral through ever more efficient and ever faster production. That kind of competitive edge is very hard to catch up.”