Scotland-based Thomson Print & Packaging Ltd was founded in 1998 by Jim and Veronica Thomson, when the company was purchased from Dennis Virtue, trading under the name Dennis Virtue Printers Ltd. At that time the company was running a pair of Heidelberg GTO two-colour presses, and a cylinder foil blocker out of a 1,500 sq ft factory based in Leith.

In 2000, the company moved to a 5,000 sq ft factory near Portobello. Here, print capacity was expanded, with the addition of two new Heidelberg presses – a four-colour and a five-colour – and a second cylinder foil blocker.

Moving into Cartons

In 2014, the company moved again to its current location in Bilston Glen Industrial Estate, in the town of Loanhead. “The move coincided with the installation of our first Gietz FSA 870 machine, massively improving both our foil production capacity and quality,” explains Jim Thomson, Managing Director. “Since then, we have also improved our print capacity with a second Heidelberg five-colour press, and in 2016 we installed a Heidelberg XL75 five-colour press, allowing us to print up to a B2 sheet size, which allowed us to start in-house production of folding cartons and boxes.”

He continues, “As demand has increased over the years for cartons, we made the decision to install a second Gietz FSA 870, this time with high pile configuration and continuous feeder/delivery. This allows us on longer runs to reduce production downtime, while still maintaining a high level of quality.”

The FSA 870 Compact is Gietz’s most flexible and efficient half sheet size-format machine for hot foil stamping, embossing, debossing and hologram application, as well as die-cutting. High quality, durability and reliability emphasise its traits. The FSA 870 Compact machine has been progressively developed over time and can be customised to fulfil all user requirements. The high pile configuration allows folding carton converters to work with deeper piles, reducing change over times and increasing productivity. Key benefits include:

- Reliable, fast, precise;

- Short change-over times;

- 150 tons of pressure;

- Dwell time;

- Longitudinal and transverse foil feed;

- Foil unwinding;

- Hologram application technology.

“We have been happy with the machine right from the start,” confirms Jim Thomson. “The team from Gietz and their UK engineers ensured a speedy installation, even considering the strict COVID-19 protocols we had to follow in our facility; the training was also quite fast, because many of our operators were already familiar with Gietz technology.”

Rebound for Whisky

“Like many industry sectors, the whisky trade went into a slow down in the spring of 2020, due to COVID-19, but also due to the tax barriers implemented by the former President of USA, Donald Trump,” continues Thomson. “However, the industry is pretty robust and now demand has picked up again from Eastern Asia and the relaxation of the trade barrier with USA, the industry is back in action and the demand for superior packaging with foiling and embossing is strong again.”

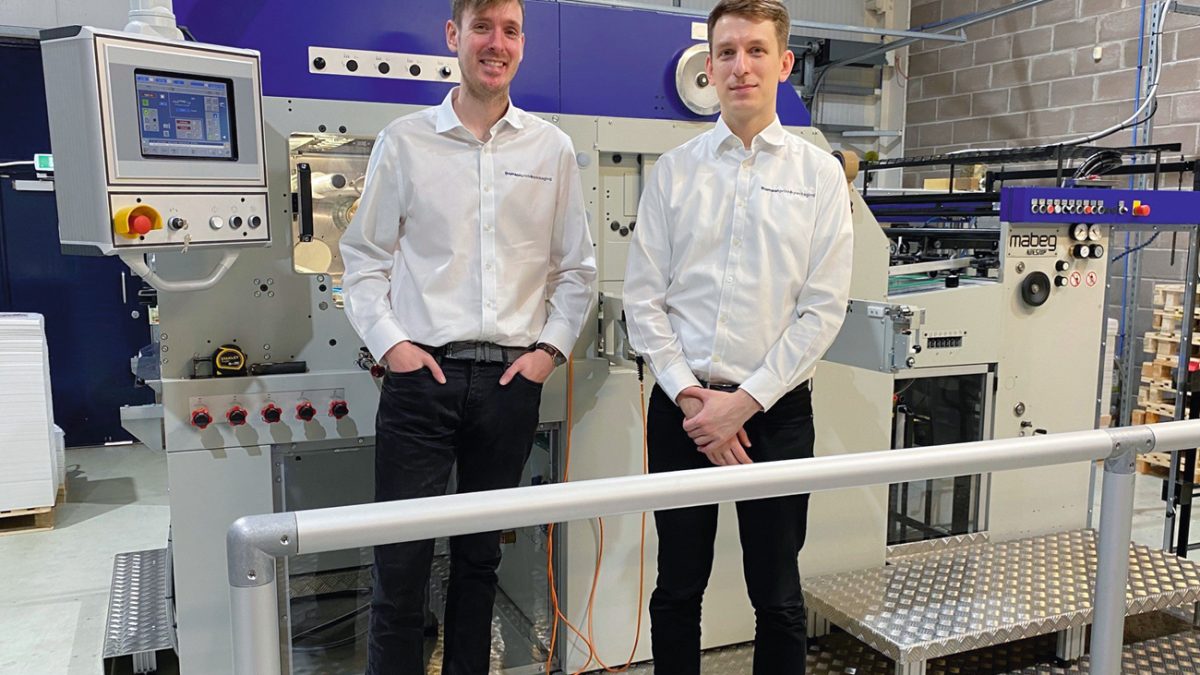

He concludes, “As a specialist supplier of carton and label solutions for the drinks industry, the growth not only of whisky but also homestead gin producers means the future looks bright for us here at Thomson Print & Packaging. With my sons in the business and the recent machinery installations, we continue to move forward and become the partner of choice for many leading Scottish brands.”