In the UK, Smurfit Kappa operates around 40 facilities, manufacturing a wide range of corrugated packaging, folding cartons and POS displays. It is also one of the larger sheet feeders to the sheet plant market. Smurfit Kappa has three sites in the UK that are dedicated to the production of corrugated sheets.

One of those sites is located in the Fishergate district of Norwich, in the east of the UK. The plant was established in the late 1980s and then known as Norwich Corrugated; Smurfit Kappa acquired the business in the 1990s.

Looking to ePS Escada

The plant has been a customer of ePS for some time, as they chose to install ePS Escada Profile Process Control System back in April 2018. The plant saw an immediate improvement in board quality following the installation.

The plant has been a customer of ePS for some time, as they chose to install ePS Escada Profile Process Control System back in April 2018. The plant saw an immediate improvement in board quality following the installation.

Like all existing ePS Escada Profile Process Control users, Smurfit Kappa Fishergate wanted to focus on improving their processes and efficiencies and invested in ePS Escada’s ‘super user’ training program, which not only provided further user system training, but identified areas of improvement within their process.

In early 2021, the Smurfit Kappa team undertook the ‘super user’ course. Due to the ongoing COVID-19 pandemic and restriction to access to the plant, ePS Escada provided this four-day session remotely. The course was structured in such a way that it allowed users and operators to interact with the ePS Escada trainers, ensuring the best possible outcome. The course provided advanced system user and process training. It also enabled the users to focus on their actual process and machinery, which once focused and corrected resulted in production improvement (quality), speed increases (output) and financial payback (ROI).

Thanks to tailored content, specifically developed for Smurfit Kappa’s Fishergate team, ePS Escada trainers took the users and operators through the system and reviewed all the processes – that way, they were able to evaluate what was actually happening on the machine when specific actions or changes were made.

One major thing that came out from the sessions was that some of the users believed that they needed different settings for every single board grade. With the tailored system approach, Smurfit Kappa were able to implement simplified settings and recipes, which ensured manageable settings were configured and used efficiently. This allowed the system to automatically make any minor adjustments, rather than having operator intervention.

Another point of daily operation that was made a priority moving forward was the importance of cleaning and maintaining sensors on the ePS Escada system, especially the temperature sensors, which allows the plant to keep control of the accuracy of the system.

“Since we completed the ‘super user’ refresher training with the customer on their PROFILE process control system, they reported zero customer complaints about warp within the first month,” says Mike Reed, Director, ePS Escada. “But like any new system installation, it is important that a plant maintains the momentum and engage with the supplier to make sure all aspects of a system are working well and the operators are happy with everything, including being comfortable with how best to get the most out of the system and their investment.”

Reed adds, “What was really interesting was that average production speeds have now increased since we completed the ‘super user’ sessions and that Smurfit Kappa Fishergate now want to engage in further sessions to cover more users, which is really encouraging. This is just one example of a customer who is prepared to invest in its people and engage with its suppliers effectively.”

Instant Improvement

Scott McKail, (pictured left) Shift Manager, Smurfit Kappa Fishergate, adds, “Since the tailored remote super user training conducted for us here at Fishergate by one of the ePS Escada Process experts, we have seen an instant improvement on board quality and a reduction in customer complaints, especially for warped board which has always been our biggest cause for returned board.

Scott McKail, (pictured left) Shift Manager, Smurfit Kappa Fishergate, adds, “Since the tailored remote super user training conducted for us here at Fishergate by one of the ePS Escada Process experts, we have seen an instant improvement on board quality and a reduction in customer complaints, especially for warped board which has always been our biggest cause for returned board.

He continues, “During the training, the ePS Escada Process expert helped us come up with a more efficient run style for our corrugator by reducing all heat settings in the hotbeds and triple stack preheaters. Since this was changed we saw a big improvement in all grades straight away and did not have a single warp complaint for over three weeks which has never happened here before. The biggest benefit we have noticed is that all supervisors, shift managers and wet-end operators have a much better understanding of how the system actually works and the importance of maintaining sensors so we have accurate readings at all times.”

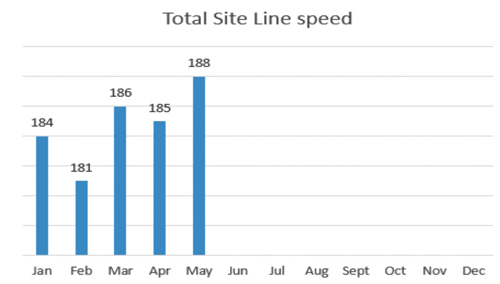

McKail adds, “We have also seen a steady improvement in line speeds as the supervisors understand the importance and benefits of running with cruise control turned on which before the training was not happening. The production line speed has seen an overall improvement so far this year. Due to the benefits and results we have seen from people receiving this training, we are going to organise more courses with ePS for further improvements that we can implement.”

New Tools

Reed concludes, “As part of our commitment to enhancing customer experience, we have also been working on several initiatives to help users of the ePS Escada solutions to stay up to date with the latest tips, methods and best practices by launching a video training Hubb. This was launched recently in May 2021 and delivers ‘espresso’ style learning to users of our Profile, Syncro and Clarity software solutions. Feedback has been really encouraging from our global customer base and we are fully committed to continually adding new and fresh content to our training Hubb on an on-going basis as our solutions and services evolve.”