The Canadian Manufacturer IMPACK Packaging confirms the successful installation of the first Ergosa Universal Packer unit at ASG Poland. In 2016, with the support of its global agency partner BOBST, IMPACK concluded the contract for an Ergosa Packer combined with a Box Turner IN-2.

With the bottleneck of the gluing department being at the delivery of the folder gluer, Szymon Polkowski, Operations Manager of ASG Poland, was looking for a supplier who could offer him a reliable and simple solution to increase the productivity for medium sized cartons. “As a result of this investment we have managed to increase efficiency by 100%, and even exceed it, without adding any extra staff,” explains Mr. Polkowski. ”Anyone buying such equipment would expect to increase efficiency but we have also benefitted from reduced job running times and increased productivity. In addition to the machine asset, we are taking care of our staff with improved ergonomics on the packing line at the end of the folder gluer.”

Packing Made Easy

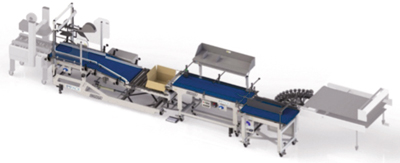

The Ergosa Universal Packer allows the packing of whole rows in either the Horizontal Mode, for smaller boxes, or in the Vertical Mode with the Perpack Module, for bigger and heavier boxes.

ASG Poland opted for an Ergosa version without the Perpack Module because of their production portfolio. They mainly use the Horizontal Mode to slide boxes into the case. “Our employees love working with the Ergosa line as it is really easy to handle and they don’t get the feeling that improved efficiency means they have to work harder.” says Mr. Polkowski.

Ergosa in Horizontal Mode with IN-2 left turn configuration.

Fast Setup

“At ASG we value the reliability of our equipment. In today’s fast moving world we are obliged to be even faster in reacting to market demands. Having said that, we have to rely on our assets in terms of utilisation time, machine availability and, of course, quality of a product. We found those same criteria with the Ergosa and IN-2 equipment,” says Mr. Polkowski.

The combination of the Ergosa with any IMPACK Box Turner not only allows the packing of a whole row of straight-line boxes into the case in one movement, but also gives the flexibility to run any box straight through without turning if the Pick & Place Mode is used. This last mode allows packing any type of boxes with one or two operators.

Ergosa in Vertical Mode with Perpack Module – packaging of bigger boxes made easy.

Packer Needs

IMPACK Packaging has been designing and manufacturing fully automatic and semi-automatic packers, as well as many additional modules, since 2001. Having patented several of these, for example the automatic batch inverters for folding carton (MFA) and most recently also for corrugated board (MFI), the company is driven to offer the latest innovations on the market. The reason for success is simple, listen to your customer. IMPACK accompanies the client from A-Z to make sure the investment in a new packer offers the highest possible productivity increase. Every product mix of a client is analysed in detail to determine the needs and every machine is perfectly adapted to each application.

As to Mr Polkowsi’s thoughts about IMPACK, he confirms that his team handled the investment project quite easily, despite the fact that for ASG they were an unknown supplier. “Service levels are excellent despite the fact that there is a time zone difference and quite a big distance between both of us. We’re now thinking about another similar investment – that’s the best testimony to the quality of the equipment we have installed.”

The Polish market is part of IMPACK’s growing presence in Europe and worldwide. After a very successful 2016 and a high number of new contacts following Drupa 2016, the company has a global presence with over 300 units installed worldwide.

Ergosa in Pick & Place mode, shown with IN-1 carton turner.