A fourth-generation family business with over 140 years’ experience and seven production sites across Europe, STI Group champions customer success at the point of sale.

STI Group is well respected in the industry thanks to innovative, sustainable and creative packaging solutions that shape markets and make it a strong partner for brands across Europe. Its customers include leading FMCG, food, pharmaceutical and cosmetics companies.

The STI Group invites its 2,000 employees to actively contribute to its development. Together, they are shaping a more sustainable packaging landscape for current and future generations.

With sales in excess of €300m, the company is headed by Jakob Rinninger as CEO and he also is responsible for Operations and Sales. Niklas Herting is responsible for Finance and Controlling, Purchasing and Information Technology as CFO. Completing the management team are Andreas Reinshagen as COO and Dr. Peter Nattermann as CIO.

“We serve branded goods manufacturers in the FMCG, food, beverage, noon food, pharmaceutical and cosmetics sectors, producing corrugated packaging, folding boxes and POS solutions at our specialised production sites in Europe,” explains Rinninger (pictured below).

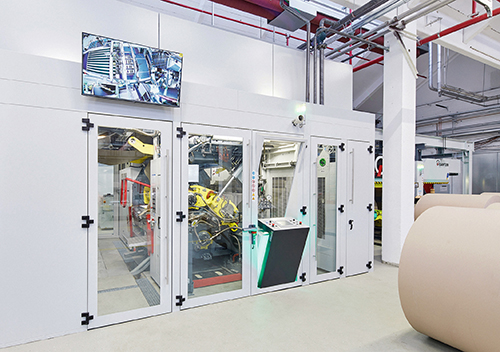

Latest Investment

The SF3 single facer, which is at the heart of the Quantum corrugator, is a revolutionary machine adopting a production process concept that is new in the corrugated industry. It is available in working widths 1.8 and 2.5m, with different configurations to meet every production requirements.

Quantum’s SF3 single facer is the ideal machine both for special applications – production of fine flutes (N and F) with very light papers up to 40 gsm – as well as for standard products. Its dimensions are very compact; the total length is between 55 and 96m, depending on the configuration. The machine offers the possibility of producing laminated corrugated board that can substitute solid board in certain applications with considerable paper savings.

In the Quantum SF3 single facer, the formation of the single face web and the application of the external liner are achieved virtually at the same time in only one thermal cycle. Furthermore the ideal labyrinth in the corrugating rolls with different diameters and the metallic pressure roll do not damage the papers. The combination of these factors as well as the fact the board is not in direct contact with the heating plates, create the following advantages:

- Higher board rigidity and mechanical strength;

- Maximum optical appearance and printing surface quality;

- Lower energy consumption;

- Easy production start up of the machine;

- Reduction of the operators involved;

- Reduced space needed.

“With the new machine, we are expanding our portfolio in the field of lightweight packaging,” continues Rinninger. “The new machine produces significantly faster and in top quality. In theory, it could replace the two existing machines at our Lauterbach site, but since we run all three laminators in parallel, we can more than double our output. In addition, depending on the specifications of an order, material savings up to 15% are possible. With the new machine, our aim is to make a considerable contribution to the field of CO2-saving lightweight packaging.”

The preparatory construction work for the high-speed machine began in summer of 2024, followed by the installation of the machine in November. “We ran the new line for the first time just before Christmas. All in all, everything went relatively quickly,” confirms Rinninger.

The Quantum’s water decks bring the basic moisture into the material, which reduces the amount of starch needed. Material coated with water-based barriers can be optimally processed. This is an important aspect for STI Group, since they promote the replacement of PE-laminated materials with water-based barriers in, for example, the food and detergent sectors.

The Stock gluing unit can be used to process very lightweight paper with optimum flatness. Sheet alignment in the laminating section is done on-the-fly which is important for further processing as it improves register accuracy in die-cutting.

The counter-pressure in the laminating system is provided by a belt conveyor instead of a conventional pressure roller. The belt technology enables more gentle pressing and therefore better quality. In addition, the newly installed technology requires less energy than other laminating systems.

“This marks a major milestone in our commitment to sustainability: thanks to the machine’s innovative technology, we are maximising resource efficiency while minimising environmental impact. A big thank you to everyone who made this possible – our dedicated teams, partners at Quantum Corrugated (part of the Fosber Group) and Stock Maschinenbau GmbH, and of course, our customers who trust in our solutions,” says Rinninger.

“Our experience was very good, we appreciated the efficient trainings and the ongoing support from Quantum,” concludes Rinninger. “We had a good start-up with the new machine and it is performing very well. Of course, this is down to the excellent working relationship we have with Quantum and Stock, we truly appreciate the good partnership.”