Pitreavie Packaging was established in 2010 and has grown substantially thanks to a combination of business acquisition, as well as product and service offerings. The Group comprises of sites that manufacture chilled packaging solutions, timber crates, transit cases and one of its newer activities, corrugated packaging.

With three sites across Scotland, Pitreavie most recently invested £5m in a new 57,000 sq ft sheet plant in Cumbernauld. The site is Scotland’s first new sheet plant in 20 years and is more than capable of manufacturing 40,000,000 boxes a year – this is the core aspect of the Group’s future growth plans.

Quickly into Stride

Since its opening, the company has been well received by customers in a wide range of industries, allowing for a further £1m investment in new equipment, including a BOBST EXPERTFOLD and another Eterna flat bed die-cutter. “We are converting in excess of 15 million sqm of board per annum, and this is set to grow,” explains Stephen Heslop, (pictured left) Group Managing Director. “We may not be the biggest corrugated box plant in Scotland, but we are well invested, innovative and we offer cost-effective packaging solutions to our customers.”

Since its opening, the company has been well received by customers in a wide range of industries, allowing for a further £1m investment in new equipment, including a BOBST EXPERTFOLD and another Eterna flat bed die-cutter. “We are converting in excess of 15 million sqm of board per annum, and this is set to grow,” explains Stephen Heslop, (pictured left) Group Managing Director. “We may not be the biggest corrugated box plant in Scotland, but we are well invested, innovative and we offer cost-effective packaging solutions to our customers.”

He continues, “Expertise and knowledge of the industry allow us to deliver inventive, cost saving solutions, with environmentalism and customer satisfaction front of mind. Our scale and capability allow us to offer cost-effective solutions with flexible lead times, which is something our larger competitors are not always able to do, especially in a tight market with extended lead times. We also pride ourselves on our ability to offer not just the corrugated box, but also the packaging consumables that go with it, including strapping, tapes and much more.”

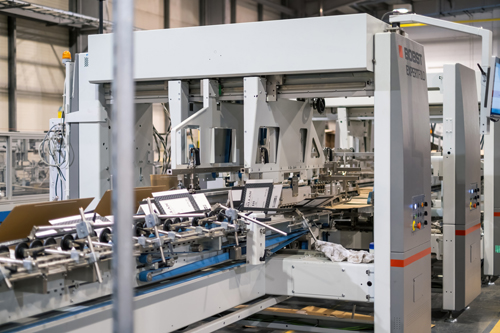

The site boasts an innovation centre where customers can bring their vision for packaging to life and take away new design samples on the same day. To date, the Cumbernauld facility has created 45 new jobs. Production is overseen by Group Manufacturing Director, Scott Alexander, a name well known in the UK packaging industry. The site has significant manufacturing capabilities with a high speed casemaker, four colour printer slotter and four colour rotary die-cutter working alongside the new Bobst Expertfold and the two Eterna flat bed die-cutters.

More Capacity Coming

“With forecast growth in excess of 40% over the coming 12 to 18 months, we continue to invest in equipment for flexo print and converting,” continues Stephen Heslop. “In June, we will be taking delivery of a new casemaker, which represents a further £1m of investment for us.”

The converting line in question is a five colour JS Machine 924 casemaker. It has been specified with additional features, including Vacuum Transfer, Doctor Blade Metering for the flexo print units and a rotary die-cutter with Serrapid Quick Die Mounting system. “This will be the first of its type in the UK and we are looking forward to installation before the summer,” confirms Stephen Heslop.

In addition to the equipment, the Group has now secured an additional 40,000 sq ft of storage space nearby. “Not only will the sheet board be delivered here, the trucks will then re-load with our finished goods for delivery to customers,” explains Scott Alexander. “It means that our sheet plant runs with very little stock of board on the floor and we convert on a just-in-time basis. To aid this, we are implementing a project to install additional materials handling and some new end of line strapping solutions, all of which will happen this year and help us enhance production output further.”

People Too

In January this year, Pitreavie announced three further strategic appointments to its senior management team – in addition to the recent appointment of Julie Russell as Finance Director – following a period of sustained growth. “Our executive team will ensure the business remains agile and is able to adapt to shifting market dynamics, while providing exceptional product and service,” continues Stephen Heslop.

Executive appointments include Commercial Director Mark Bruce, who was previously Brands Director for Finsbury Food Group and Sales Director for Border Biscuits. Operations Director, Gary Grindlay, joins the group with over 30 years of experience in managing large, complex supply chains in the food, drink and pharmaceutical sectors. Commercial Manager, John Blaney, formerly Sales Director at Boxes and Packaging and most recently General Manager at Encase.

Raymond Loggie also joined the business in early February, as Operations Manager, to oversee the increasing corrugated production demand. He has a wealth of experience in the corrugated sector over many years in the UK and Middle East.

“You can see that food and drink is a key growth market for us, and that is why we have recruited some key people who have valuable experience in the food and drinks industries, both at a commercial level and also a logistics and supply chain level,” concludes Heslop. “The new converting line and the enhanced materials handling within the Cumbernauld facility will allow us to grow our business comfortably over the coming year, ensuring we offer the best in class service for customers throughout the territory.”