In today’s highly competitive business environment, producing high quality products with increased efficiency are not just catchphrases, they are a necessity. Ever since 1947, Albany Packaging has remained committed to providing the highest quality folding carton products to well-known grocers, restaurants, convenience stores, apparel and retailers across North America.

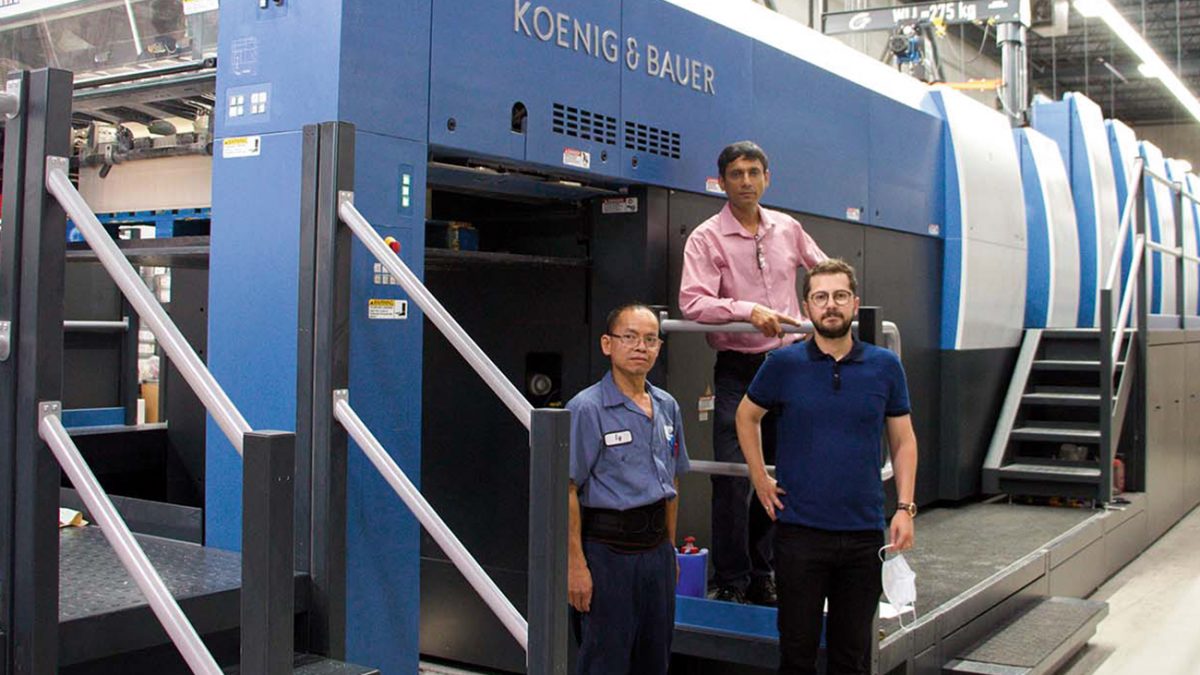

For more than 70 years, this professional folding carton solutions supplier has specialised in the sheeting, printing, die-cutting, windowing, and gluing of paperboard. As business has skyrocketed, its solution to increase capacity was to recently install a new Koenig & Bauer Rapida 145 seven-colour press along with a Koenig & Bauer AllPro 145 folder gluer. Since it went live, the new press has provided a 60% increase in press productivity and has saved the company set-up time, while reducing waste and job turnaround time.

“We believe that our commitment to manufacturing efficiency is the driver behind our continual success,” says Daniel Engelberg, Sales and Project Manager, Albany Packaging. “Being one of the few packaging manufacturers that provides large-format production in Canada, we are fortunate enough to have the capabilities to adapt to ever-changing market trends and meet customer specific requests. Our investments in large-format equipment, such as our new Koenig & Bauer Rapida 145 seven-colour press, Koenig & Bauer AllPro 145 folder gluer, dual-lane window machines, and tray-former have increased overall plant productivity by 26% this year.”

Located outside of Toronto, the 87,000 sq ft facility in Markham, Ontario, totals over 50 employees. Its customer base, which is situated throughout North America, is comprised of 50% grocery accounts, 40% in the custom print market, 8% in the food service industry (specifically restaurants and bakeries), and 2% in the apparel market.

“We’ve experienced tremendous growth in our custom print division,” says Engelberg. “With decades of experience, we work with our customers to design and build custom boxes for bakery, cupcake, donuts, and other food packaging items like food trays and additional packaging supplies that suit their needs. Having the new Rapida 145 allows us to efficiently produce that work, which calls for shorter run lengths with more creative designs for particular holidays and other special work.”

Armed with the new Koenig & Bauer Rapida 145 large-format press, Albany is utilising its seven-colour units and QualiTronic color control system to deliver the specific logos and branding that its customers demand. Not only does the new press assist Albany’s customers with high quality, but it strengthens its reputation in the marketplace as a provider that saves on makeready times and can easily produce consistent colour-matched packaging. Albany’s notable customers include national grocers such as Sobeys, Longo’s, and Metro, notable restaurants and convenience stores such as Boston Pizza and 7-Eleven, as well as retailers like Dick’s Sporting Goods.

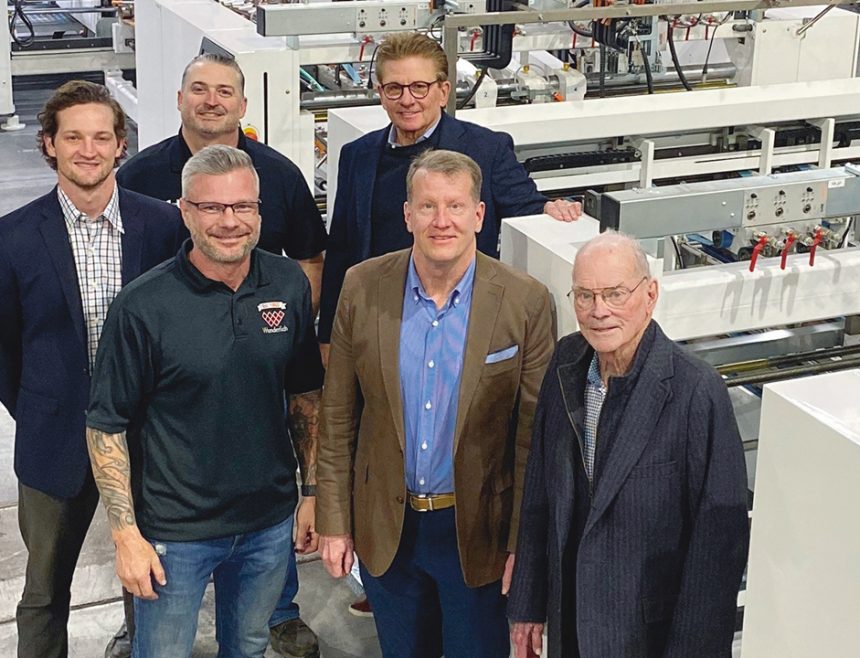

The Koenig & Bauer AllPro folder gluer is one of Albany’s more recent additions to its facility, bringing a total of four machines to its post-press delivery. It’s an important addition, says Engelberg, because it provides more capacity and increases the size of the packages that can be produced. Everything is now automated, he says, and this department is consistently displaying much higher speeds and efficiency.

Left to right: Marek Dajnarowicz (Head of the Finishing Department), Zaheer Akram (Production Manager) and Daniel Engelberg, (Director of Business Development and U.S. Sales).

Sustainable packaging is a key component of Albany’s mantra. “As consumers continue to seek sustainable and eco-friendly packaging solutions, we’ve placed our efforts into forming relationships with paperboard suppliers that value and echo these environmental concerns,” says Engelberg. “As for production, we always make sure that our products are made of recyclable, high-density paperboard – allowing for improved durability and performance.”

Engelberg concludes, “Our goal is to provide our customers with a positive experience throughout the entire process and create the highest-quality designs for them. When we deliver on those two-fold areas, we have succeeded in conveying our friendly, efficient, and reliable service and retaining another happy customer. That’s how we measure our company’s success.”