Cases24 is an integrated site using high quality corrugated sheet manufactured by sister company, Board24. The cases manufacturing operation was originally created to build on Board24’s offering to the packaging industry and is focused on producing the same exacting standards of quality and service.

Launching in April 2009 with one Latitude casemaker, the business has since installed a further three machines to keep up with increasing demand. “Consistent, repeat business has underpinned the growth and we are thankful for the loyalty demonstrated by our long standing customers,” says Alex Morris, Managing Director of Cases24. “It remains a point of pride for the business that the first saleable cases produced in 2009 were sold to a customer who remains a loyal customer to this day.”

Supplier of choice

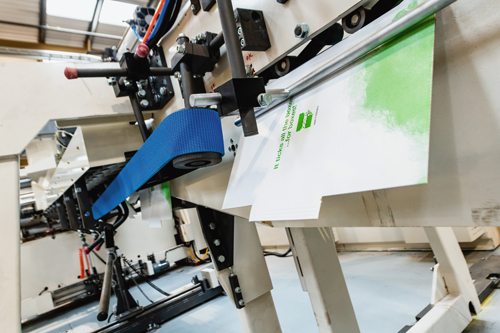

The evolution and addition of new Latitude casemakers over the past 10 years has driven a focus on efficiency, which led to Cases24 most recent installation, benefitting from full automation, from pre-feeder through to take off, all supplied by Dücker Group. The adaptation to new latest generation technology by the team of operators, maintenance and support staff has ensured casemaker 4 has been a success within the first six months of operation.

The ‘make it possible’ ethic that drives the success of Cases24 is thanks to the focus and determination of the experienced team, some of which have contributed to the success since 2009, including the company’s well regarded customer services team.

Debbie Newbold has been a member of the customer service team for Cases24 since its inception. “Over the last 10 years, there have been many changes; initially I was the only customer services administrator involved with Cases24. We had one casemaker and now this has grown to four, all of which can produce a variety of case sizes, die-cut cases and three colour cases across a considerable choice of different paper types.

“We have many new customers however it is lovely that I am still speaking to some of the same customers and in some instances the same contacts from 2009. Our knowledge and capabilities have grown considerably offering more complex box styles and this is very much thanks to the investment in the new Latitude casemakers.”

She continues, “In the beginning we had to work out palletisation by hand which was very time consuming, the introduction of enhanced and improved systems has been a great asset to further improve our customer service.”

Industry first

Cases24 is the first company in the UK corrugated industry to be operating four Latitude casemakers. The machines were sold by Latitude’s UK and Ireland sales agent, GTS (Europe) Ltd. David Williams, Managing Director of GTS, says, “We have been working closely with Cases24 right from the start. From the delivery of the very first Latitude machine back in 2009, we have been by their side to help ensure maximum uptime and the best quality cases. The fact they have now installed four is testament to the quality and reliability of the Latitude equipment. It has been a pleasure working with them and we look forward to taking the relationship into the next 10 years.”

Paul Elliott, Conversion Manager for Cases24 for six years, has witnessed and implemented many improvements. He adds, “Other changes to Cases24 have included a new ink kitchen to mix inks on site, which is a great time saver and also a mezzanine floor for stereo storage. We also moved to Pamarco’s EFlo anilox rolls for better control of flood printing and tone work and introduced a spectrometer to measure colour at a tight Delta reading. We have an understanding of which suppliers are best placed to offer us industry leading service and quality; some have supplied us over a number of years.”

Morris concludes, “Cases24 began with an opportunity to supply volume glued cases to the trade and thanks to the continued support of our customers and the strong manufacturing team it has proven successful. We are beginning our next step of growth with the recent installation of casemaker 4. Given our customer centric approach, product quality and service we feel confident we can deliver the ‘make it possible’. Ultimately we make it possible for our customers and we hope that will serve us well.”