“There’s an undoubted fact that digital printing makes our packaging stand out from the crowd,” says Mr. Rangnoktai, Executive Director of leading Thai packaging enterprise, INTER. Interestingly, the company recently started up a digital printing business unit to service a growing demand from local customers.

“In actual fact, every customer of INTER that has sen our digital offering has been impressed by the innovation, vitality and development momentum from various colourful and creative corrugated displays, as well as fruit cartons and display packaging,” notes Rangnoktai.

“In actual fact, every customer of INTER that has sen our digital offering has been impressed by the innovation, vitality and development momentum from various colourful and creative corrugated displays, as well as fruit cartons and display packaging,” notes Rangnoktai.

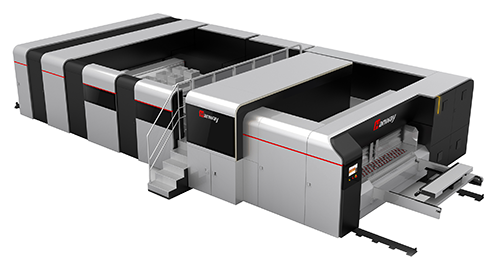

INTER is a Thai family owned business that has been making corrugated boxes since 1980. In 1990, it began to invest in corrugated machinery including corrugators, and subsequently a paper machine in 2006. In 2018, it started to move into digital printing, with the installation of two Hanway high-speed single pass digital printers, promoting the ‘upgrading of productivity’. Today, INTER is one of the leading corrugated packaging and paper manufacturers in Thailand, providing production capacity of one million sqm of sheet board per day.

Digital Move

“Since the beginning, speed and high service levels have been the key focus for our business. These principles have helped us grow each year, offering faster services and competitive differentiated products for our customers,” said Rangnoktai. “However, the batch sizes have been getting smaller and 300-500 boxes per order has become an industry standard. Proofing and prototyping took up much time using conventional methods and costs became another severe challenge that pushed into adopting digital technology.”

He continues, “We are quite confident about this investment for our company’s future. We want to find new value for our products, to sit alongside good service and competitive prices for our customers. Thanks to Hanway, sharing their digital equipment, technology, experience and services with us, makes our packaging different from other companies in the sector.”

He continues, “We are quite confident about this investment for our company’s future. We want to find new value for our products, to sit alongside good service and competitive prices for our customers. Thanks to Hanway, sharing their digital equipment, technology, experience and services with us, makes our packaging different from other companies in the sector.”

Through digital and intelligent technology, INTER have saved a great deal of upfront labour cost, waste and converting steps, and obtained more efficient delivery and better product quality – even creative presentation and new marketing opportunities.

“Since we have installed this machine, an urgent order can be accepted in the morning and delivered in the afternoon. Customers can see a printing sample without paying for the printing plate, and many customers are interested in this technology.” Rangnoktai added.

New Opportunities

“Packaging is not only a protective container, but a representation of the brand and the product inside,” says Rangnoktai. “Nowadays, INTER is trying to create stand-out packaging with our new digital press, especially for new products that need to be eye-catching, able to turn heads and that make people want to try them.”

He continues, “We installed the Hanway Glory2504, a 2.5m single pass digital printer, the biggest single pass digital machine in SE Asia. Back in 2018, we purchased a Glory160X and this has been providing convenience for our high-speed production.”

Benefitting from the flexible, efficient and premium digital press, INTER’s business patterns have changed a lot, and they can accept more types of orders, including small lots, urgent orders, single orders and prototype orders – and answer more customer’s requirements on order changes and delivery. Rangnoktai concludes, “For customised packaging, the new digital press offers superior order quality compared with offset printing, lifting our corrugated business to a new level.”