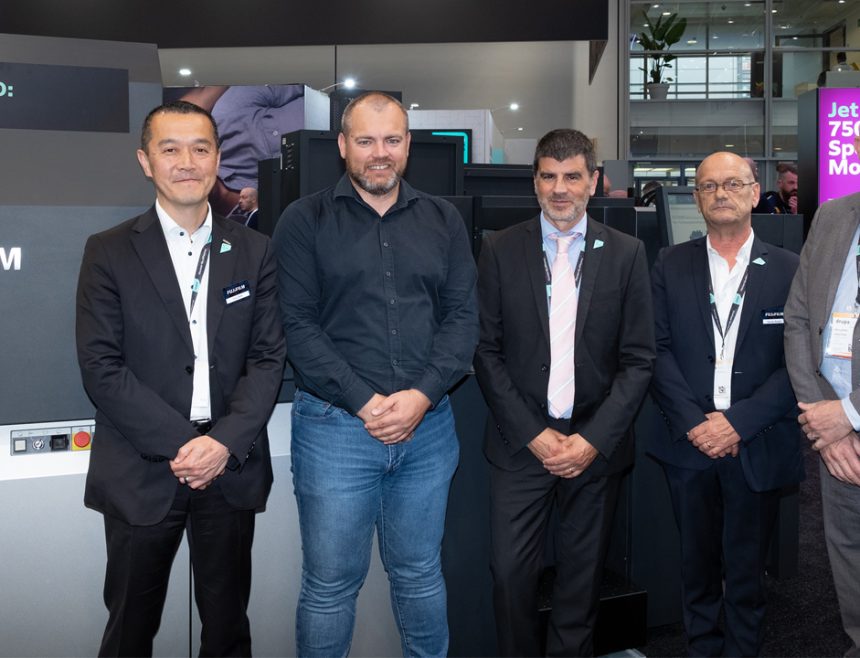

Front row, left to right: Jason Fujikawa (Press Supervisor), Sanford Morioka (President), Gerald Gakiya (Pressman) and Duane Kong, (Vice President of Sales). Back row, left to right: Alex Upton (Vice President of Operations) and Ben Hauger (Pressman).

Edward Enterprises, like many printers in business for sixty-five years, has weathered innumerable challenges throughout its long history. Despite these challenges, the Honolulu based company continues to find new ways to reinvent itself.

Needing a press capable of expanding its burgeoning folding carton business, Edward Enterprises recently installed a Speedmaster CX 104 from HEIDELBERG. The new six-colour press equipped with UV curing replaces two older presses and has improved the plant’s throughput and efficiency.

Founded in 1959, Edward Enterprises is the largest locally owned printing company in Hawaii. From traditional offset and digital based printing, to email and web based media, Edward Enterprises has a variety of solutions for its customers. Edward’s team helps its customers integrate and manage these options so they can communicate more efficiently and effectively. Its latest service includes the design and manufacturing of folded carton packaging.

As an ESOP company, each employee is also an owner of the business. The pride of ownership makes Edward’s team strive to meet higher standards. Its primary focus is to provide perfect service to all of its customers.

More Output, Less Shifts

After fifty years of commercial printing, Edward Enterprises began producing its first folding cartons almost ten years ago when it installed a Varimatrix die-cutter and Easygluer folder gluer – both from Heidelberg.

“Heidelberg was there for us every step of the way, educating and training us year after year,” said Alex Upton, Vice President of Operations, Edward Enterprises. Shifting more of its business from commercial to packaging printing was always part of the company’s long-term plan, but in 2020, the pandemic accelerated that shift even faster. Wanting to further improve its packaging capabilities and efficiency, Edward Enterprises installed a new Speedmaster CX 104-6+L in May to replace its twenty-five-year-old CD 102 and XL 75. Since installation, the press has cut the company’s maintenance costs and consumables usage in half.

“Our need for a new press was pure necessity,” said Upton. “We planned to purchase one earlier, but then the pandemic happened. Our CD 102 had over 350 million impressions, and its outdated UV and coating system limited our capabilities and the type of folding carton work we could run.”

Running at 15,000 sheets per hour, the new CX 104 has increased the company’s print capacity. The new press is fully equipped with Heidelberg’s latest technology, which includes autonomous Push-to-Stop technology and a completely new operating philosophy, the Heidelberg User Experience (UX). Coupled with the patented Intellistart 3 and other assistance systems, Heidelberg UX ensures short makeready times and the best possible support for press operators throughout the press run.

Edward Enterprises selected the CX 104 based on its speed and the types of jobs and quantities the company typically runs.

Upton continued, “Heidelberg played a huge part in helping us determine the specs that would best serve our existing customers and our expected growth.”

After running only a few months, the CX 104 produces more work in two 8-hour shifts than the company could produce with three 10-hour shifts on its two older presses.

Edward Enterprises has significantly reduced its production time and waste thanks to the press’s state-of-the-art UV curing system. The company, who produces many cartons for chocolates and candy sold throughout Hawaii, often runs these boxes with four colours plus UV with a strikethrough coating. With the outdated drying system on its older press, Edward’s team had to resort to multiple passes through the press to achieve the desired effect. “This presented a lot of its own issues,” said Upton. “Being able to do this in one pass on the CX is a game changer for us.”

In Good Hands

To further boost its efficiency, Edward Enterprises chooses to use Heidelberg’s Saphira Consumables and Prinect Production Manager. “The advantages of Prinect are the colour accuracy between proof and press and its seamless integration to the CX 104,” said Upton.

He concluded, “All of our Heidelberg products have played a key role in our ability to grow our business’s capabilities over the years. With Heidelberg, we always know we’re in good hands. They have unbeatable support and expertise. They’re all great people too.”