colordruck Baiersbronn, a packaging service provider operating throughout Europe, is an all-rounder known for its high quality standards. Right from an early stage, the company started to build itself a new business model based around digital printing and counts among their customers industrial and commercial enterprises in the food, confectionery, beverage, pharmaceutical, cosmetic and non-food sectors.

It has collaborated with Heidelberg on numerous projects, giving rise to a decades-long partnership. colordruck Baiersbronn was one of the first field testers of customised digital packaging production using the Heidelberg Primefire 106. With almost all criteria successfully met and the Primefire 106 fully adapted to colordruck Baiersbronn’s web-to-pack portal, the field test was successfully completed at the end of 2019.

“Through the consistent development of a digital business model, we were also able to further optimise our processes and make them fit for the future,” says Martin Bruttel, Managing Director of colordruck Baiersbronn. “Heidelberg provided outstanding support as a partner in incorporating the Primefire 106 into our workflow. Wanting to offer our discerning customers new business ideas in digital packaging printing meant that our requirements for the digital printing press were very high. Working with the team from Heidelberg, we have now met these requirements and are more than happy with the results for our customers.”

The two Managing Directors of colordruck Baiersbronn, Thomas Pfefferle (top row, far right) and Martin Bruttel (bottom row, centre) as well as Sabrina Janta from Heidelberg (top row, far left) together with their teams learned a lot during the field test.

Variable data printing

Three years ago colordruck Baiersbronn added the ‘Packaging Digital’ division, which offers innovative packagings in runs of one and up with the online shop www.designyourpackaging.de

A complex issue in building the new business model with the Primefire 106 was the variable data printing (VDP), the prerequisite for mass customisation. “The team have invested a lot of expertise and effort here, and developed VDP together,” explains Tom Streefkerk, who heads up the Packaging Digital division at colordruck Baiersbronn. “Today, the Primefire can produce an unlimited number of custom printed sheets without any interruption and in consistently high quality. The Primefire 106 has been gradually integrated into the existing production workflow, with the Prinect Digital Frontend (DFE) as the link between the hardware and the software used.”

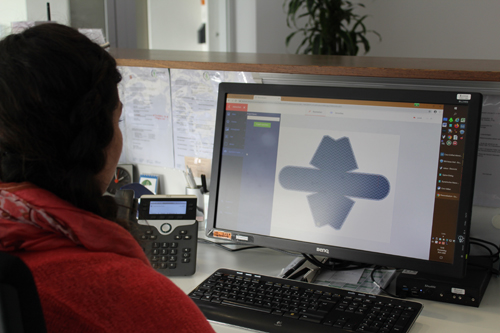

Customers can design their own custom packagings on colordruck Baiersbronn’s web-to-pack portal.

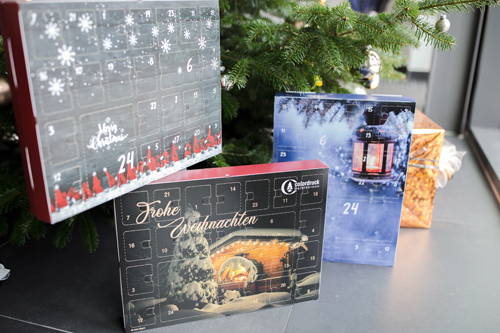

The converter’s digital business model includes the web-to-pack portal and the Primefire 106 as an output system. This makes it possible to produce the most varied applications in many packaging segments. For example, the custom and personalised Advent calendar is already a bestseller among business and private customers. The company has acquired a multitude of new customers and its existing customers are impressed with its expanded services. “The Primefire offers excellent colour brilliance, outstanding register accuracy, the same impressive colour consistency, and good reproducibility. Customers who attach particular importance to these criteria will have an immediate benefit,” adds Streefkerk.

The custom and personalised Advent calendar is already a bestseller among business and private customers. It is printed on the Primefire 106 at colordruck Baiersbronn.

“colordruck Baiersbronn had high requirements for digital packaging printing, which we were able to meet by working together and will continue to develop together in the future,” explains Montserrat Peidro-Insa, Head of Business Unit Digital at Heidelberg. “We learned a lot on both sides and thank colordruck Baiersbronn for adding to our knowledge of digital business models.”

Offset transfer to digital

In addition to digital printing, the company also produces premium packagings using offset printing on four of the most recent generation of highly automated Speedmaster presses. Shorter runs are increasingly being transferred to digital printing to free up capacities in offset. colordruck Baiersbronn offers its customers systematic solutions for adapting spot colours in offset and digital printing.

“The integration of digital printing allowed us to gain a lot of flexibility and optimise our efficiency in all run lengths. Digital printing is setting new standards in colour fidelity across the entire run,” concludes Managing Director, Thomas Pfefferle. In addition, the B1 format of the Primefire 106 enables the company to use die-cutting tools in postpress that are also used for offset runs.

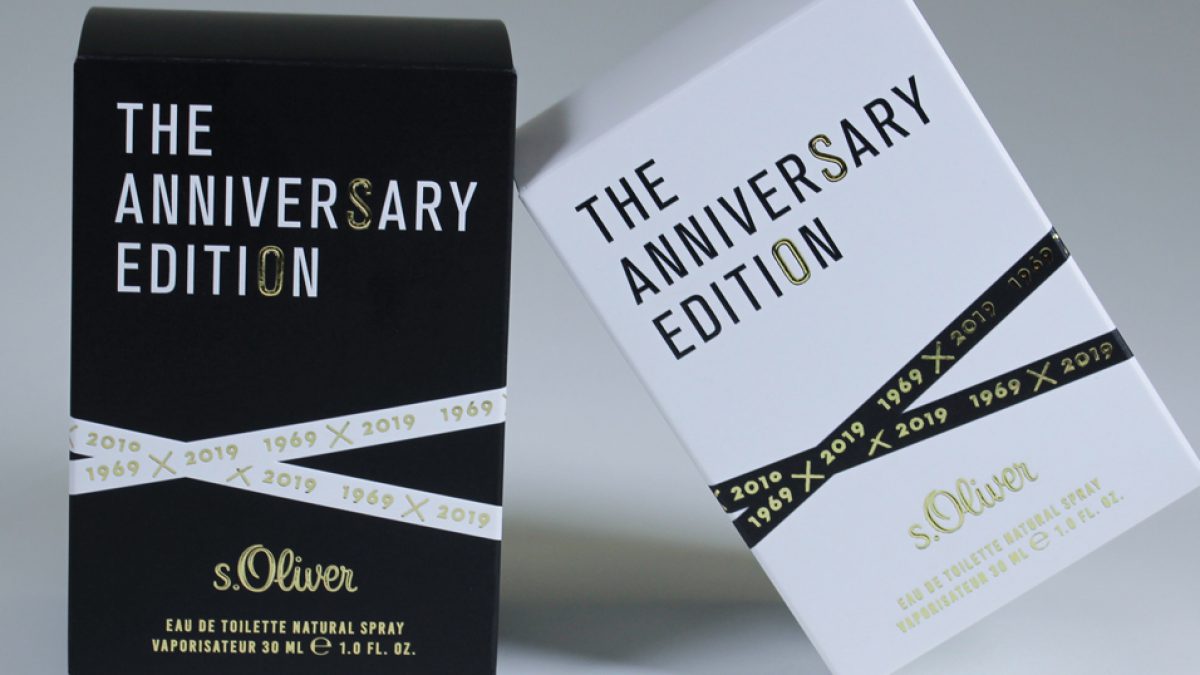

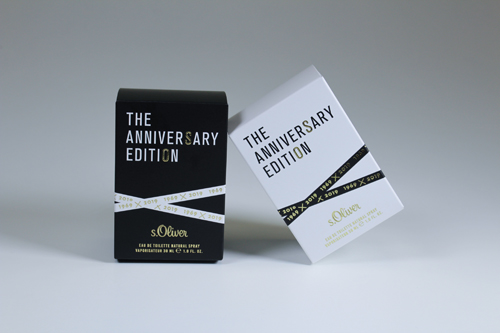

The special edition of a well-known parfum brand was produced on the Primefire 106 by colordruck Baiersbronn.