In June 2021, BHS Corrugated digitally printed the first customer order on a web which was guided instantly into the corrugator for processing it to digital printed corrugated board immediately. It was achieved at the pilot customer, Schumacher Packaging in Greven, Germany.

Project History

Since the early 2000s, BHS Corrugated has been striving for the vision to make digital print a component of the corrugating process. The idea of ‘Inline Printing’ was born. The digital print technology for industrial applications was tracked and basic research was conducted. At drupa in 2016, various printing press manufacturer showed that the inkjet technology is ready for high-volume applications in the corrugated segment, where speed, uptime and working width are crucial. At the same time, BHS Corrugated began the collaboration with Inca Digital Printers Ltd located in Cambridge, UK, to jointly develop a customised Print Engine for the application by BHS Corrugated. This collaboration was based in a framework with a formal agreement with SCREEN GP from Japan, the parent company of Inca.

Additionally, BHS Corrugated scaled up its in-house digital print resources, thus the formal Research & Development project was established and started. In 2018, the company accomplished the first inhouse prints, followed by the inhouse approval by the pilot customer in July 2020. Next the machine was de-assembled at the BHS Corrugated headquarters in Weiherhammer, Germany, transported and re-assembled at the customer site. Already in December 2020, the first test print at the pilot customer site – a small Christmas tree – was again performed successfully.

What was the Reason?

In retrospective for BHS Corrugated it was clear, that mature inkjet technology offers a once in a lifetime chance for the company to diversify its portfolio and to take part in the transition of print in corrugated box plants for the digital decade to come. These developments will enable BHS Corrugated to be well prepared for the digital decade that the corrugated industry is entering which will bring a revolution of print, processes and machinery layout in box plants.

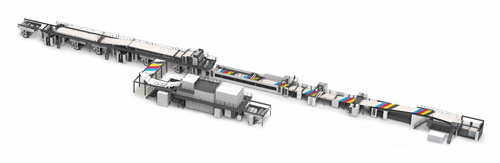

BHS Corrugated is planning to provide high-end and high-speed solutions and is convinced that the integration of Digital Print – inline – during the corrugating process will be the superior option which will deliver significant benefits to its customers. In this context ‘Inline Printing’ is labeled RSR® (Roll to printed Sheet in Real Time). Up to now, Digital Print Solution before the corrugating process (pre-print) and after the corrugating process (post-print) are available for the corrugated segment. With RSR®, BHS Corrugated develops the technology to combine two process steps and differs significantly from other Digital Print Solutions in the corrugated industry. The company says this technology will become a real game changer.

Project Proof at Pilot Customer

At the end of 2020, the RSR® Printer moved to Schumacher Packaging for its box plant at Greven, Germany. Schumacher Packaging and BHS Corrugated de-assembled, shipped, re-assembled and commissioned the machine. It took only six months from loosening the first screw at BHS Corrugated to the first test print at the customer, despite the COVID pandemic. This underlines the business relationship between both companies. In March 2021, the first customer order was printed in the ‘roll to roll’ mode.

First Inline Print at Customer

The premiere took place in June 2021 at Greven. After the first roll-to-roll prints, it was also successfully printed ‘inline’ in the RSR® process for the first time: A customer order was digitally printed on brown paper, the printed web was immediately guided via turning bars into the corrugator and successfully processed into finished digitally printed corrugated sheets. The finished boxes were successfully sold in the market. The format cuts of the corrugated board were made in the dry-end of the corrugator using a variable and digital imprinted QR code which was processed by the new preprint systems iCMC and iLFS. At this premiere, speeds of up to 250m/min were achieved. This result was more than confirmed at further test production runs which took place a few weeks later in July 2021. During a 5-hour non-stop production, a top speed of 300 m/min in the RSR® process was achieved, leading to an output of more than 30,000 sqm per hr of sellable corrugated board.

Benefits of the RSR®

BHS Corrugated says that the advantages of the RSR® Process are obvious. The paper roll doesn’t need to be wound up, stored and transported anymore. By that, the RSR® Process raises the flexibility in the production and shortens the time-to-market significantly, because the pre-printed orders on the paper roll are not predefined chronologically anymore. Instead, the paper is digitally printed on demand in real time and will be in real time converted to finished corrugated boards in the desired priority and quantity.

Björn Schumacher, CEO, Schumacher Packaging Group, said, “With RSR®, we have the flexibility to consider design and quantity changes by our customers right up to the last moment.”

Consequently, as a result, unnecessary overproduction in pre-print can be avoided, because in case of unplanned additional demand, the order can be reprinted on-demand and immediately processed into corrugated board. You just print what you need. Printing speeds of up to 300 m/min and working widths of up to 2.8m enable a high-volume productivity and a most flexible order planning on the entire working width which are requirements for the needs of the corrugated board industry. These high-output metrics coupled with process advantages result in maximum productivity, fast time-to-market, and low cost per sqm. Eventually, the RSR® Printer is the prerequisite for the ‘Box Plant 2025’ as seen by BHS Corrugated.

Outlook

The Beta machine in which significant experiences from the alpha machine have been incorporated is currently in the technical design phase. The series release is planned in 2024. BHS Corrugated has set the course for RSR® Digital Printing.

The Beta machine in which significant experiences from the alpha machine have been incorporated is currently in the technical design phase. The series release is planned in 2024. BHS Corrugated has set the course for RSR® Digital Printing.