Located in one of the largest cities in Texas – San Antonio – Diamondback Corrugated Container LLC is one of those great stories of a fresh start-up by a guy with plenty of industry experience and the hunger to leave a stable job and set up his own business.

Founded in July 2016, the company is run by John J. Bradley Jr, who boasts a CV including some of the industry’s leading names – PCA, Temple Inland and Bates Container. Bradley set up the business with three other partners, who include John and Paul McLeod of Lone Star Corrugated. His background in corrugated goes way back though – Bradley had worked at his grandfather’s business, Accardi Corrugated Box in Philadelphia, where he worked in the summers while at school, learning about boxes, people, and how to take care of customers and employees. He moved to San Antonio in 1992, where he joined Bates Container.

So where does the name come from? “Well, John and I quite liked the idea of a snake within our logo and of course, the Diamondback is indigenous for this area,” recounts Bradley. An image of the famous snake is intertwined within their box certification logo, something that quickly shows the user where their corrugated box came from, in the heart of Texas.

So where does the name come from? “Well, John and I quite liked the idea of a snake within our logo and of course, the Diamondback is indigenous for this area,” recounts Bradley. An image of the famous snake is intertwined within their box certification logo, something that quickly shows the user where their corrugated box came from, in the heart of Texas.

Early Growth

As you would expect of a company run by people who really live and breathe corrugated, Diamondback grew pretty quickly in its early years. Discussing their site in San Antonio, Bradley says, “It is a good space for sure, and our plans are to try and increase our storage area by a further 40,000 sq ft over the coming years,” explains Bradley. “We have always been about service and quick reaction times. We have become well known for getting customers out of a jam when they need packaging real fast – and as a result, those customers stick with us. It’s all about consistency and OTIF – on time, in full delivery.”

The company is a fast growing sheet plant, that is for sure. With a three color MWU flexo folder gluer, three color S&S FFG and a two color Langston Saturn II FFG, the company has utilized used equipment to get itself where it is today. “We are not about fancy graphics just yet, we are about making good quality, single, two and three color boxes for customers that we service within about 100 miles of our facility,” adds Bradley. “With a fleet of our own small format trucks, we can deliver rapidly from stock if necessary, keeping our customers well serviced. Texas is a massive state to service, so we decided to concentrate on customers within a close proximity, rather than try and spread our net too thin. In addition to this, all sales are handled by me and my daughter – Madison – and being a true independent, of course we both undertake additional functions in the business as well.”

Focussing on producing packaging for the food and drink sector, as well as the medical industry, the company employs 21 people and operates from an 80,000 sq ft facility. Annual sales are expected to reach $12m in 2024.

New Equipment Added

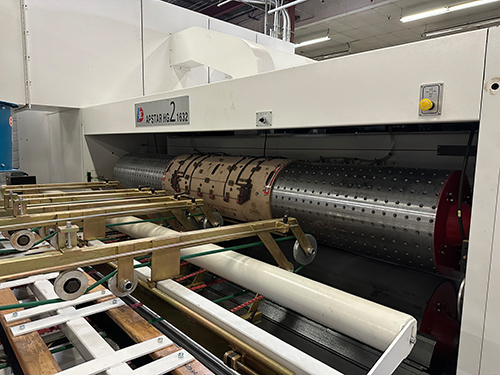

In the Fall of 2023, the company took delivery and start up of a new Apstar HG2 1632 flexo rotary die-cutter. Supplied by Haire Group, the line also features the fourth Apstar-specific stacker.

The APSTAR HG2 series is setting a new standard of performance in the corrugated industry with cutting-edge technology that comes standard on every machine. Every important feature necessary for flexo printing and consistent production rates is incorporated on the Apstar HG2 rotary die-cutter.

With its extended feed and print sections, inline sheet cleaning, chambered ink metering with twin ink pumps, and its ability to easily expand with your market opportunities, this rotary die-cutter includes many standard features to ensure your success. These include:

- SUN Lead Edge feeder;

- SUN MircoGrind for a consistent cutting and creasing surface;

- Siemens PLCs and touch screens throughout;

- Impulse dust management system;

- Complete computer controls for faster set-ups and repeatable quality;

- Extended length vacuum transfer feed section for better feed to first down print registration;

- Praxair anilox rolls, CUE blankets, Rexroth, ABB, SEW Euro drive, and ARO.

“This new line is certainly churning out a lot of work for us, and the customers are very happy with the quality of boxes being printed and die-cut on this new line,” states Bradley. “The guys at Haire and Hampton Industrial did an awesome job during the install, and Ben Liskey has really created a solid relationship with us. The instructors have been fantastic and our team of operators have taken very well to the machine. I must admit, it is sometimes hard to get the operators to run the older equipment, as they are so excited about the new Apstar!” he jokes.

“We have invested for our growth,” concludes Bradley. “We would like to grow the business by threefold in the next five years – and thanks to the investment in the Apstar, plans for expanded warehousing and a really loyal team, we are on track to exceed this.”