For businesses seeking robust, reliable, and entirely bespoke packaging solutions, Harleys Corrugated Cases stands as a name built on over 60 years of expertise. Based in Leicester, UK, this privately owned company has cemented its reputation by marrying four generations of family heritage with an unwavering commitment to quality and customer service.

As a leading independently owned sheet plant in the UK market, Harleys offers a comprehensive service that covers the entire packaging lifecycle: design, manufacture, and final delivery. They are experts in creating custom corrugated boxes, fitments, and specialised packs, confidently handling everything from a standard shipping box to complex, bespoke die-cut solutions — and they do so for any size, any quantity, even offering next day delivery for short orders. This made-to-measure approach, supported by their in-house design service and the latest CAD technology, ensures every customer receives a perfect-fit packaging solution that is both cost-efficient and structurally sound.

What truly sets Harleys apart is their dedication to both customer satisfaction and environmental responsibility. Having built a solid reputation for attention to detail, they pride themselves on being a name the industry trusts. Crucially, they have championed the move toward sustainable packaging. All of their materials are 100% recyclable and entirely plastic-free, allowing companies to meet their logistical needs while upholding their own green commitments. With a reliable team facilitating fast manufacturing and logistics, Harleys is positioned as a partner ready to efficiently deliver quality corrugated products that help businesses succeed in a demanding market.

Changing of the Guard

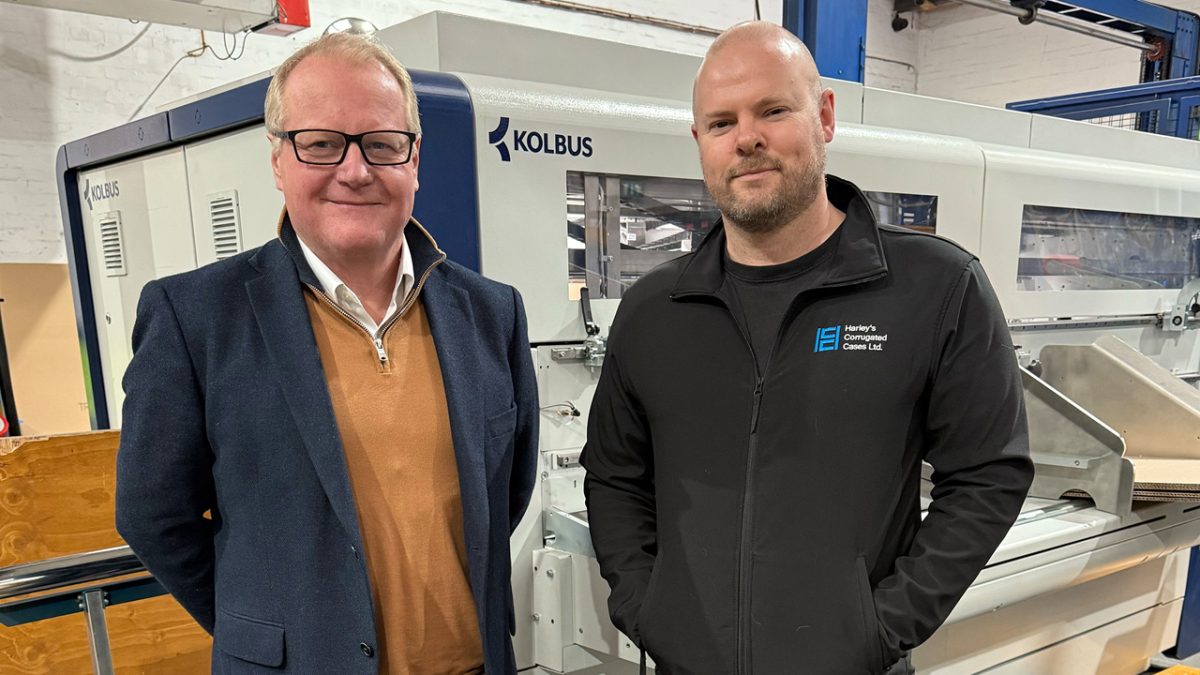

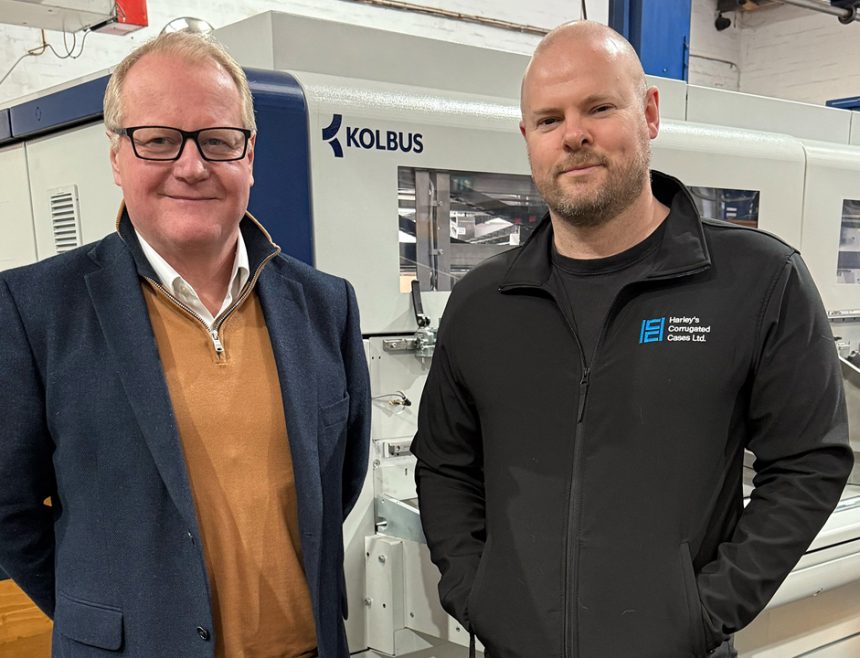

In 2024, the company went through a generational transition. “My parents decided to step back from the business and allow me to take over the company by way of a generational buy-out,” explains David Harley, Managing Director. “I’ve worked in the business my entire working life and could see areas where we could enhance our offerings even further, so we set about looking for equipment to bolster our manufacturing capabilities.

“We worked closely with Mike Irving of M&K Trading, who installed a reconditioned three colour Dong Fang 1224 flexo folder gluer, which has been a big boost for us,” adds David Harley. “But the one area of the business we really wanted to enhance was our short and medium run work, particularly following the installation of a Kolbus MN400 MultiNova gluer in late 2024. We already had two Autobox and two Solarco boxmakers and we decided to boost this area of the business. We visited drupa in May 2024 with the team from Kolbus UK and saw their new BX Motion on their stand. We then saw one at their Houghton Regis facility, before making the decision to invest.”

He continues, “It really is a game-changer for us, as the print and die-cut in one pass is the right fit for our business. Being able to send jobs direct to the machine from the design office is an amazing function, meaning we get jobs turned around even faster than before. Customers benefit from digital print, without the cost or lead-time for having a flexo plate made for single colour jobs.”

BXM in focus

As part of its latest investment plans for expansion, Harleys recently started up a new BX Motion (BXM) short run boxmaking line, manufactured by KOLBUS Group GmbH. The BXM was installed and commissioned in the early autumn, moving in to full production mode in November.

“We are delighted that Harleys have chosen this high performance, German-engineered solution for short run boxmaking,” said Greg Bird, Managing Director, Kolbus UK. “This is the second BXM we have installed in the UK, and we know it will give Harley’s a real advantage in their marketplace. The Kolbus BXM can make customised boxes from single, double, and triplewall board. Each module can be individually adapted to specific requirements, including the sequence of individual processes. Transport rollers and tools are positioned automatically according to FEFCO code and format and automated adjustment of all creasing/cutting tools for precise positioning in less than 60 secs makes this an easy to operate high performance workhorse. An autofeeder and stacker allow for automatic one-man operation, and a digital print unit, which comprises three individual 140mm print heads, allows for printing of logos and basic images at high speed.”

Easy to use

Although the team at Harley’s are well versed in short run boxmaking equipment, the new BXM has been a significant step change. “We know short run inside out, but this new machine, with the easy to use touchscreen and super fast job change is like night and day compared to our other equipment,” said Rich Gallagher, Production Foreman. “It is intuitive, easy to set and all the operators have taken to it quickly and easily. It really is a great piece of kit.”

“The support from Kolbus has been great,” adds David Harley. “Like any new machine, there will always be teething problems, but their team were reactive and fast to solve any issues. We can’t fault Kolbus and we are proud to be one of only two companies in the UK to have the BXM.”

David Harley concludes, “The investments over the last year or so are all about enhancing flexibility. As we look to continue growing the business with our customer base across Leicestershire and Northamptonshire, the addition of these new machines means we are solidly placed for the next decade and more.”