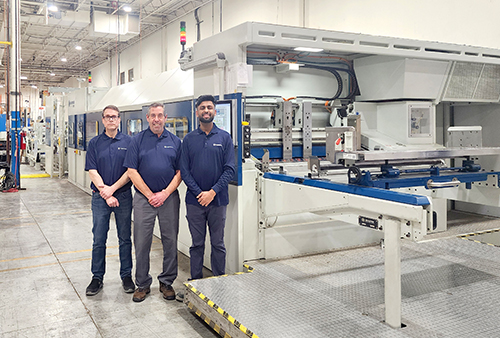

Planet Group, a provider of innovative and sustainable packaging and marketing-at-retail solutions, has expanded its digital print capabilities with the installation of a Domino X630i digital aqueous inkjet corrugated press at Hughes Decorr, part of the Planet Group of companies in Concord, Ontario, Canada.

The investment strengthens Planet Group’s ability to support brands from concept to shelf by delivering high-quality, full-colour digital printing directly on corrugated packaging with greater speed, flexibility, and efficiency.

Planet Group brings together multiple companies to support customers across the entire packaging supply chain from structural design and print to manufacturing, fulfillment, warehousing, and distribution. The organisation specialises in corrugated packaging, POP displays, co-packing, warehousing, and distribution, helping brands launch programs faster, move product efficiently, and meet retailer and consumer expectations with innovative, sustainable solutions.

Creative engine for marketing-at-retail

As part of Planet Group, Hughes Decorr serves as the organisation’s creative and shopper-marketing engine, delivering marketing-at-retail and display solutions that help brands stand out in-store. Hughes Decorr specializes in POP displays and packaging, working closely with Planet Group’s production, co-packing, and logistics teams to provide a fully integrated solution from design and production to packing and distribution.

“This integration allows us not only to design the display or package, but also to produce it, pack it, and move it through the supply chain as a single, coordinated solution,” says Jason Berns, President, Planet Group.

Broad corrugated capabilities across multiple markets

Planet Group produces a wide range of corrugated packaging solutions, including brown boxes, retail-ready packaging, shippers, trays, display components, and specialty formats for heavy or oversized products. The company supports everything from short-run, fast-turn programs and seasonal launches to large national rollouts and ongoing replenishment programs.

Its customer base spans food and beverage, health and wellness, personal care, household goods, pet, industrial, automotive, and specialty retail markets all requiring packaging that performs efficiently throughout the entire supply chain.

Sustainability Built Into the Process

Sustainability is integrated across Planet Group’s operations, from design and manufacturing to customer collaboration. The company continuously works to reduce material usage, improve recyclability, optimize palletization, and support retailer and brand sustainability goals.

Hughes Decorr contributes through initiatives such as investing in Life Cycle Assessment tools to validate environmentally responsible packaging decisions, aligning with Packaging Golden Design Rules to reduce plastic waste, and ensuring zero production scrap goes to landfill through strict waste-reduction practices.

Why digital, and why Domino?

Planet Group identified digital printing as a critical capability as customer demand grows for shorter runs, faster turnarounds, customisation, and campaign flexibility. After evaluating digital solutions designed specifically for corrugated, the company selected Domino for its robust platform, aqueous ink technology, and strong service and support model.

“The Domino X630i gives us the ability to offer high-quality, full-colour digital printing directly on corrugated with minimal setup time,” says Stephen Longmire, VP of Sales, Hughes Decorr. “It allows us to help customers move faster, reduce inventory, and maintain strong brand consistency.”

Customer benefits and new opportunities

With the Domino X630i, Planet Group can help customers launch programs faster without printing plates, run multiple versions or retailer-specific programs, test new concepts or limited releases, and maintain consistent branding across short runs and reorders.

The press also enables Planet Group to pursue more short- and mid-run branded packaging, retailer-specific versions, rapid prototyping, pilot programs, and seasonal or promotional work that was previously cost-prohibitive using conventional methods.

From a production standpoint, the Domino X630i is expected to reduce make-ready times, improve throughput on versioned projects, increase flexibility for mixed runs, and deliver consistent colour on repeat digital work translating into quicker turnarounds and more reliable delivery for customers.

A strategic growth investment

Planet Group views digital printing as a strategic growth driver that complements its existing conventional corrugated capacity. The Domino X630i is expected to help attract new customers, deepen partnerships with existing brands, reduce the risk of obsolete inventory, and better align with retailer demands for fast, flexible packaging solutions.

Partnership and support

Planet Group reports satisfaction with Domino’s training, service, and support, citing hands-on operator training, workflow integration guidance, and responsive service as key benefits.

“For us, the Domino difference is the combination of a robust technical platform with a genuine partnership approach,” says Mike Bannerman, General Manager, Hughes Decorr. “It’s not just about the hardware it’s about collaboration, optimisation, and long-term success.”

Looking ahead

As packaging and retail marketing continue to evolve toward shorter life cycles, more frequent artwork changes, and greater customisation, Planet Group expects Domino to play a central role in enabling agile, on-demand corrugated production.

“With the Domino X630i and the broader Planet Group platform behind it, we are strongly positioned to help customers navigate where packaging and retail marketing are headed… faster, more targeted, and more sustainable,” concludes Bannerman.