Multi-Packaging Solutions (Limerick) has been trialling the latest Pin technology from C&T Channel Matrix, the manufacturer of creasing matrix. KINGPIN and SPEEDPIN were added to the C&T portfolio of products for the die-cutting industry in 2017. Both patented pins offer converters a reduction in make-ready times, reduce consumables cost and improves conversion efficiencies.

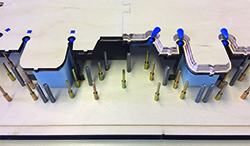

Southern Ireland based Multi-Packaging (Limerick) has been testing KINGPIN for several months. They have seen excellent results in reduced downtime, with an average 20-minute reduction in the make-ready process. Paul McCormack, Cut & Crease Manager at Limerick explains the many benefits of KINGPIN. “Setting up new jobs can be very time-consuming and we need to have fast turnarounds and reduce make-ready time wherever possible. On complex jobs, make-ready time can take as long as 40 minutes, but this has been eliminated in some instances with the use of KINGPIN as they replace the use of locating pins and rings entirely and instead, this permanent pin is inserted in the die-board for the lifetime of the die.”

The company often has one die-board for up to 30-40 different plates. Having to reposition and reset the pins for each plate was very time-consuming and is now no longer required. There is no need to remove KINGPIN from the die as it self-retracts automatically into the die board upon transfer of the counter to the plate. When new counters need to be laid for the different plates, KINGPIN can be simply reactivated, allowing the make-ready process to be repeated using the same die.

Mr McCormack added, “Previously pins could also come out and damage the plate resulting in downtime – this worry is eliminated as the pin is pushed and retained into the die. Registration is achieved every time as we have found the KINGPIN to be very stable and there is less movement than traditional pins giving improved crease alignment that is spot-on every time.”

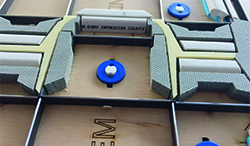

SPEEDPIN is another new concept from C&T. Fitted directly in the female stripping board by the die maker it completely eliminates the need for costly stripping frames and bottom pins. It also offers considerable time saving in terms of set up and therefore increases machine efficiency. Multi-Packaging (Limerick) has also been using the new SPEEDPIN and has found that doing away with the pin frame has further dramatically reduced consumable costs and make-ready time as there is no need to either fit the frame into position or align bottom pins to the male stripping unit. “This gives a real benefit in time-saving in our cut and crease department and has eliminated the actual cost of the pins and frames. On average, we save around 15 minutes per job when we use SPEEDPIN,” added Mr McCormack. In summary, he expressed the relationship he has with C&T. “Having a strong level of technical support, with a positive attitude, has been extremely beneficial for us at Limerick. These new innovative pins have allowed us to be much more efficient by reducing prepress time and taking actual costs out of our production.”